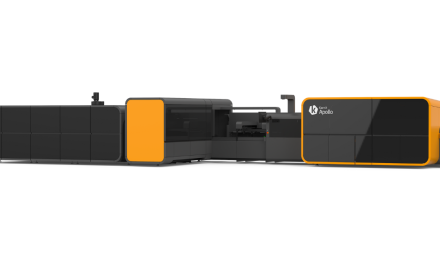

Leading flat knitting machine builder Shima Seiki has introduced a wide needlebed version of its SVR technology, designated SVR202. It supports a variety of production needs with its wide 80-inch knitting width and tandem knitting capability. High productivity is achieved with a maximum knitting speed of 1.4 mtr per second and the R2CARRIAGE System that permits quicker carriage returns.

It also carries over established Shima Seiki technology such as the renowned Digital Stitch Control System (DSCS), Spring-Loaded Full-Time Sinker system and Stitch Presser. According to Shima Seiki, proven technology, along with Made-in-Japan quality, reliability, productivity, userfriendliness and cost-performance all combine to satisfy the high expectations of the world’s fashion industry.

Wide Gauge

Special knitting needles on SVR202 realise Wide Gauge capability whereby a variety of gauge from finer-gauges using all-needle knitting, to lower-gauges using half-gauge knitting – can be knitted on a single machine. This, Shima explains, allows the freedom to handle changing seasons and shifting trends without investing in a machine for every gauge or resorting to the complex, time-consuming task of gauge conversion.

Rapid response R2 Carriage system

The R2Carriage (R2=Rapid Response) System features an advanced carriage mechanism combined with improved software programming that achieves quicker carriage returns after each course.

Tandem capability for flexible operation

SVR202 also features twin carriages, each with a single Knitran system. While both carriages can be used together along the entire width of the needle bed in double-system mode, the carriages can be separated into two single- Knitran CAM systems for knitting two identical pieces, such as collars, simultaneously. Tandem operation allows a single SVR202 to perform two separate roles, significantly increasing the versatility and productivity of the machine.

DSCS

Considered one of the most significant breakthroughs in modern-day knitting, Shima Seiki’s patented Digital Stitch Control System (DSCS) continuously adjusts yarn feed and tension to yield loop consistency with tolerance to within ±1 per cent. The result, Shima says, is quality control capability that is virtually impossible with conventional analogue systems. In addition to being an essential element in quality shaping and integral garment production, DSCS allows consistency among different batches and repeat orders. “DSCS is the only proven digital system field-tested and market-proven in the industry for over 30 years. No other manufacturer can claim this kind of experience or level of refinement,” Shima says.

User-friendlier knitting machine

SVR202 features an new full-colour LCD touch-sensitive control panel with a larger screen that greatly improves on the previous monochromatic display. Still at eye-level, the new control panel maintains established ergonomic benefits by carrying over function buttons for simultaneous use of both hands. Easily accessible USB interface and network connection continue to provide improved access in data transfer. For those moments when power suddenly becomes unavailable, a backup power supply allows work to resume after power failures. SVR202 is available in gauges 7, 12 and 14 in its SV format, and in gauges 7, 8, 10, 12, 14 and 16 in its SC format