Determine Your Fabric Requirements

Determine Your Fabric Requirements

The first step is to clearly define the type of fabric you want to produce and the specific characteristics required.

• Fabric Type & Thickness: Double jersey machines can produce fabrics ranging from light, soft jerseys to thicker, more complex fabrics. Depending on the thickness and texture of your fabric, choose a machine with the right gauge (needles per inch).

• Weave Pattern: Double jersey machines can produce a variety of patterns, including plain, ribbed, or jacquard fabrics. Determine whether you need simple structures or more intricate patterns.

• Fabric Performance: If you’re producing stretch fabrics (e.g., spandex of Lycra blends), ensure the machine can handle elastic fibers or other specialty yarns with affecting fabric quality.

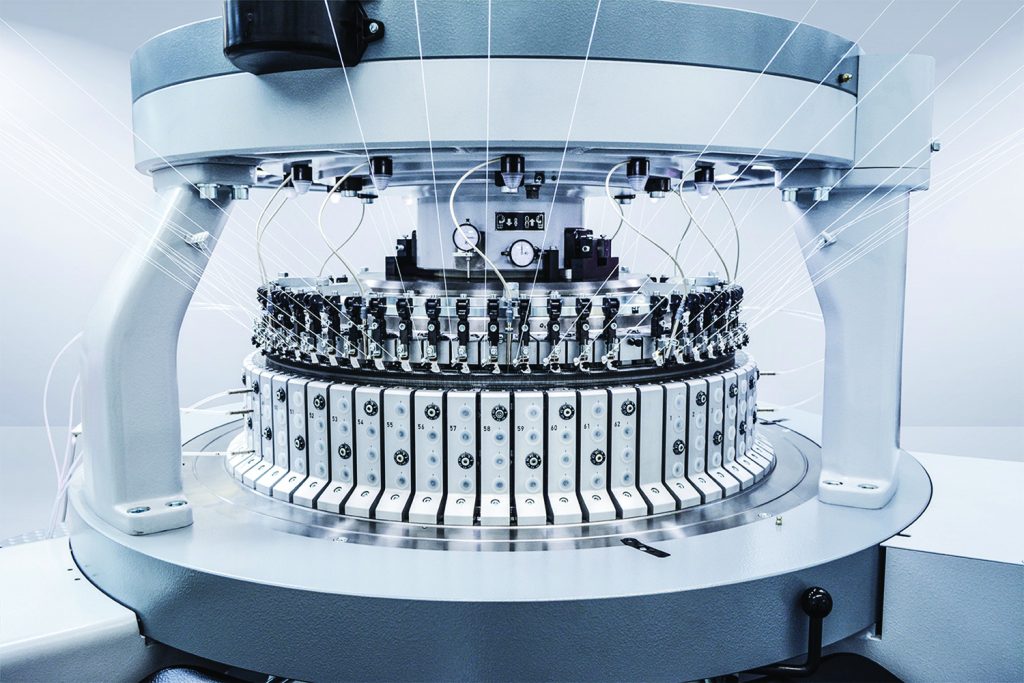

Gauge Selection (Needles per Inch)

• The gauge of a circular knitting machine refers to the number of needles per inch. The guage will influence the fabric’s texture and density:

• Fine Gauge (e.g. 32 to 50G): Suitable for lightweight fabrics like t-shirts, lingerie, or other soft, delicate fabrics.

• Medium Gauge (eg, 18G to 30G): Ideal for medium-weight fabrics such as activewear, knitwear, or casual clothing

• Coarse Gauge (e.g., 12G to 16G): Used for heavier fabrics like sweatshirts, blankets, or upholstery fabrics

A finer gauge produces a softer, smoother fabric, while a coarser gauge is better for thicker, heavier fabrics.

Fabric Quality Control

Look for machines with built-in features that ensure fabric quality:

• Tension Control Systems: Some modern machines have sophisticated yarn tensioning systems that help maintain consistent yarn tension, preventing fabric defects like puckering or uneven stitching.

• Elastic Control Systems: Machines with automatic stretch control can better handle elastic yarns, ensuring that fabric elasticity remains consistent and without distortion.

• Automatic Fabric Inspection: Machines with automatic fabric inspection systems can detect defects such as holes or loose stitches during production, which can save time and reduce waste.

Yarn Type and Yarn Feed

Double jersey machines can accommodate various types of yarns, including cotton, polyester, wool, nylon, and elastane.

• Single/Double Yarn Feed: Consider how many yarn feeds your production needs. A double yarn feed machine can work with two yarns simultaneously, improving efficiency and flexibility for complex fabrics.

• Elastic Yams: If you’re working with stretch fabrics, ensure the machine can handle elastane spandex blends effectively. Machines with special attachments for stretch yarns can be beneficial.

• Flexibility: Machines with adjustable speeds are versatile, allowing you to vary production rates depending on the fabric’s complexity and yarn type

Brand Reputation and Technical Support

• Brand: Look for reputable manufacturers with proven track records in the circular knitting machine industry (e.g., Terrot, Santoni, Jingmei). These brands typically offer high-quality machines and robust support networks

• Technical Support: Ensure the supplier provides good technical support, including training, troubleshooting, and access to spare parts

Cost and Return on Investment (ROI)

• Initial Investment: Double jersey knitting machines can vary in price depending on the brand, features, and customization options. Assess your budget and weigh it against the expected production volume and fabric quality

• Operating Costs: Consider operating costs like energy consumption, maintenance, and yarn consumption. Machines that are energy-efficient and easy to maintain can provide better long-term savings

• Maintenance and Support: Choose a machine from a reputed manufacturer with good after-sales support. Availability of Spare parts, local servicing and technical support are essential for minimizing downtime

• Yarn Tension Control: Check the machine’s ability to adjust yarn tension accurately, as this will affect the fabric’s smoothness and the final product quality

Machine Diameter

The diameter of the knitting machine affects the fabric width and production capacity:

• Smaller Diameters (e.g., 18″, 24″): Generally produce narrower fabrics, suitable for smaller widths of fabric like cuffs, collars, or narrow bands

• Larger Diameters (e.g., 30″, 36″): Suitable for producing wider fabrics such as those used for garments, bedsheets, or larger apparel pieces. Larger diameters are often used for higher

Machine Speed (RPM)

The speed of the machine is a key factor in determining how much fabric you can produce within a certain period. Higher speeds are great for large-volume production but can sometimes sacrifice the quality of the fabric if not properly calibrated.

• Production Volume: If you are focused on high-volume production, choose a machine with higher RPM capabilities. For example, 200-250 RPM machines are commonly used in largescale manufacturing

Production Requirements and Future Growth

• Production Capacity: Understand your current production needs and forecast future growth. Opt for a machine that can scale with your business. For example, if you plan to expand your fabric offerings, invest in a machine that can accommodate a wider range of yarns, patterns, and fabric types.

• Flexibility: If you need to produce a variety of fabric types and patterns, choose a machine that offers easy configuration changes and adaptability. Multi-functional machines allow you to produce different fabric structures without needing a separate machine.

Automation Features

Automation plays a significant role in improving efficiency and reducing manual intervention.

• Automatic Yarn Changeover: Some machines allow for automatic yarn changes, reducing downtime and ensuring smoother production, especially for complex color or material shifts

• PLC Control System: A Programmable Logic Controller (PLC) is essential for managing machine operations, controlling stitch length, and adjusting speed. This also allows for storing fabric settings, making future setups quicker and more efficient

• Centralized Lubrication and Cleaning Systems: Machines with automatic lubrication and cleaning systems ensure that the machine is regularly maintained, reducing downtime and increasing the longevity of the equipment