Texcom, as Buenos Aires headquartered Texameri S.A. is officially called, is one of the leading companies in Argentina with more than seventy years of experience in the market. With three production plants, a commercial office, and six retail stores spread around the country, Texcom manufactures and distributes knitted fabrics for a high demand market, where sports, technical, fashion and workwear fabrics stand out.

Texcom, as Buenos Aires headquartered Texameri S.A. is officially called, is one of the leading companies in Argentina with more than seventy years of experience in the market. With three production plants, a commercial office, and six retail stores spread around the country, Texcom manufactures and distributes knitted fabrics for a high demand market, where sports, technical, fashion and workwear fabrics stand out.

The company’s own developments, such as Twintex, Polisap, Neodry, Sense, and Texcom antibacterial, are said to be perfect for sports and leisure due to their technical attributes. The company attaches great importance to the fact that all processed materials have the appropriate current environmental certificate (Öko Tex Standard 100, BlueSign and ZDHC). The efficient and responsible use of chemicals is also a matter of course.

Texcom has become a strategic partner for its customers, basing its operation on three pillars – market focus, innovation, and sustainability.

These pillars position the company one step ahead of the needs and demands of the market through technology and development. With more than 100 circular knitting machines and a wide range of possibilities for rotary printing, sublimation, lamination as well as special finishes such as antibacterial or hydrophilic, Texcom produces premium sports and leisure wear. This includes the official jersey of one of the world’s most successful national soccer teams, the white and sky-blue striped Albiceleste jersey of Argentina.

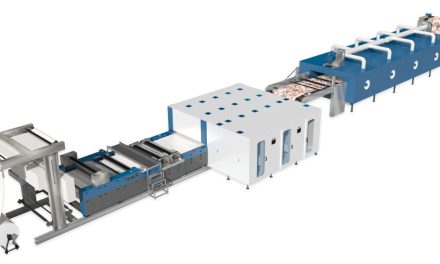

Texcom has recently started up two new Brückner Power-Frame stenters for knitted fabric with eight compartments and lubrication-free vertical chain and direct gas heating. This is the fifth Brückner line purchased by Texcom and the successful continuation of the cooperation with Brückner since 1979. The third member of this successful alliance is the commercial agency, Mapeko, which has been active for Brückner for several decades and in the third generation.

The partnership between the German market leader in textile finishing machinery and Texcom has always been trustful and good over the changeful development of the Argentinian textile industry and several generations on both sides.

Highest drying capacity and the technically proven splitflow ventilation system, the extremely homogeneous air volume and temperature distribution due to countered thermo zones were decisive for the customer. The low specific energy consumption of the direct gas heating and the maintenance-friendly components, such as the completely lubrication-free vertical circulating chain and width adjustment spindles, help to save production costs, especially in economically difficult times. Especially in the premium sector, the exactly reproducible finishing results due to full automation, as well as recipe management of the line are appreciated.

Mr. Esteban Scigliano, Industrial Manager (Gerente Industrial) at Texcom is confident: “With the energy-efficient high-tech machines by Brückner we follow the continuous changes in Argentina and will be part of the upswing of the domestic textile industry. We invest in innovation to promote the sustainability of our processes by an optimal use of the thermal energy consumption and a maximum saving of electrical energy. The technology of these machines ensures us a higher quality and the ability to produce in a sustainable and efficient way, reducing energy consumption. We thank the whole team of BRÜCKNER who made this possible.”

Regina Brückner, CEO of the German market leader is pleased about these positive impulses for the Argentinian textile industry: “Especially in a crisis, companies are in demand which look ahead and go their way future-oriented. Texcom is setting a good example and setting standards. We are pleased to be a long-standing partner and friend of the innovative and ecologically oriented Texcom Group.”