-

Dr. Prabir Jana, President, TANTU

-

Dr. Ram Sareen, Head Coach, Tukatech, USA

-

Anshuman Dash from H&H

-

Savannah Crawford, Chief Collaborator, Tukatech, USA

-

Shayama Prasad Goswami of Kesoram Rayon

-

Sanjib Sinha, General Secretary, TANTU

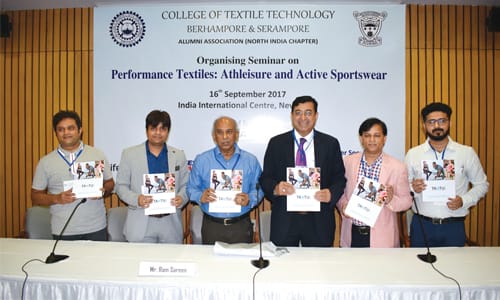

5th TANTU seminar on Performance Textiles: Athleisure and Active Sportswear was held on September 16, 2017 at India International Centre, New Delhi. There was exciting gathering of industry experts, academicians, professionals and Govt. officials from all over India discussing on athleisure and active sportswear.

Dr. Prabir Jana, President, TANTU and Seminar Chairman in his brief welcome address, mentioned the seminar as anwatershed event in the Athleisure and Active Sportswear segment in India with experts from nine brands represented in the panel discussion and as many as seven brands are Indian. He pointed out that probably for change, Indian manufacturers are thinking and working proactively matching up the pace with global growth pattern.

Dr. Ram Sareen in his keynote address emphasised the fit of athleisure product and how global industry is using technology like 3D simulation and pattern printing to shrink the supply chain lead time. The first panel discussion covered major challenges are faced by home grown brands and manufacturers. Some of the common issues discussed by panel members are unavailability special fabric for activewear products, domestic brands are still small in volume production, unavailability of synthetic fabric and trims in the local market, importing of small quantity of various items, synthetic fabric dyeing and unavailability of skilled professional in running special machines, and dyeing synthetic fabrics.

In reply to the question why they choose to start activewear brand for domestic market, Roshan Baid, owner of the brand Alcis, said that he gets satisfaction and gratification by manufacturing sportswear brand for the domestic market and able to provide the Indian people a good sportwear product with better price compared to international brands. The difference in set up for a normal garment and active sportswear garment include – special fabric, special technology for seaming and some special stitching machines. The technology offerings are becoming so sophisticated that irrespective of customer requirement any polyester garment coming out of manufacturing unit now finished with moisture management and antistatic finish.

Bhupinder Singh, Head Creation Centre & Sourcing, Wildcraft, India explained how Wildcraft is addressing the product development through “creation workshop” where textile, product, industrial, chemical all engineering meet to innovate a product through use case scenario, keeping the comfort of human body at the core. He also pointed “To get success as a sportswear brand one needs to build a differentiating factor in their product. One can get big market share for a short time by selling the product at cheaper price but depending on the cheaper price a brand can’t sustain for long run.”

Sanchit Khurana, the youngest brand owner among the panel speakers, shared his learning in the process of brand building and developing activewear products. Though they have experience of manufacturing active sportswear product for international top sportswear brand, they have recently launched their brand. He feels marketing a brand is big challenge to them.

Indu Sharma from Delta Galil, explained the difference between two terms – athleisure and activewear. According to her “Activewear is a clothing designed to be worn sports, exercise and outdoor activities. On the other side, athleisure lies at the intersection of activewear and traditional sportswear.”

Yoga clothes the right example of athleisure product. She also elaborated various kinds of product varieties – like sleep wear, shape wear and sportswear. Deepankar Sekhri from Decathlon explained how Decathlon is helping the manufacturers with technical expertise to source and produce speciality fabrics as well as trained manpower.

Savannah Crawford of Tukatech in her address emphasized the criticality of creation of right body form, identifying motion patterns and continuous addition of new fabric properties as the key for 3D sample making for athleisure and activewear.

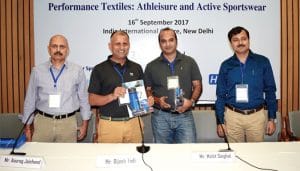

Mohit Singhal, the Founder of Aurro, had started selling their sportswear product on the online portals and later they have opened physical stores. Bijesh Todi, Co-Founder of T10 sports prefers the online channels for selling their activewear products.

They cater more on the customised sportswear products. Anurag Jaichand from Woodland tells why the physical store is still important to gain customer share. End users need to be educated on the end use of active sportswear products, how the product is made for, and one to one customer education can be better through selling goods on the brick and mortar store.

Shayama Prasad Goswami of Kesoram Rayon apart from encouraging athleisure and sportswear brands to diversify to include rayon into the fibre mix, also stressed on the alternative cellopackaging as more environment friendly option. Anshuman Dash of H&H mesmerized the audience with his stitchless collection of knitwear products and invited the athleisure and active sportswear manufacturers to explore the stitchless option at his innovation lab due to several advantages over traditional sewn garments.

While the panelists agreed on the point that it is synthetics that will drive the athleisure and active sportswear market, however recyclable and biodegradable polyester and different blend of natural fibre and ingredients will drive the environment friendliness index. Innovative ideas are somewhat shackled by lack of availability of quality fabrics and quality accessories and now large athleisure and active sportswear brands are investing in backward vertical integration. While the panelists credited Alcis to lead the disruption in polyester processing facility in India, all condemned the textile mills for not creating world class polyester fabrics in India.

The discussion was concluded with the note the athleisure and active sportswear market will grow in India in the near future. Domestic brands need to reach rural market and small cities and they need to educate young generation on various kinds of sports to enlarge the active sportswear market size. Secondly, active sportswear manufactures need to develop raw material suppliers locally for different kind of trims required for manufacturing their products without compromising the trims’ quality.