Leading computerized flat knitting innovator Shima Seiki Mfg., Ltd. of Wakayama, Japan is exhibiting at the 19th Dhaka International Textile & Garment Machinery Exhibition (DTG 2025) in Dhaka, Bangladesh, in cooperation with its partner Pacific Associates Ltd. Operating in Bangladesh since 1996, this is the fifteenth time the Japanese manufacturer is participating in DTG.

Leading computerized flat knitting innovator Shima Seiki Mfg., Ltd. of Wakayama, Japan is exhibiting at the 19th Dhaka International Textile & Garment Machinery Exhibition (DTG 2025) in Dhaka, Bangladesh, in cooperation with its partner Pacific Associates Ltd. Operating in Bangladesh since 1996, this is the fifteenth time the Japanese manufacturer is participating in DTG.

As the second-largest textile exporter in the world, Bangladesh is looking to upgrade its textile industry through innovation, digitalization and sustainable production. The market is therefore keen to establish effective business models that support such production. In response, Shima Seiki continues its strong presence within the market through its lineup at DTG, emphasizing its core strength in cutting-edge Wholegarment® knitting technology.

Capable of knitting an entire garment in one piece without the need for linking or sewing while using only the material required to knit one garment at a time, Wholegarment® knitting is well-known for promoting sustainability in the knit factory. The company is showing its MACH2®XS153 WHOLEGARMENT® knitting machine in 15L gauge which features 4 needle beds and SHIMA SEIKI’s original SlideNeedle™, capable of producing high-quality fine gauge Wholegarment® knitwear in all needles. SWG®091N2 “Mini” Wholegarment® knitting machine shown in 15 gauge provides opportunities in Wholegarment® knitting across a wide range of items in a compact, economical package. A different approach to Wholegarment® knitting is also presented in the form of the N.SVR®183 machines. SHIMA SEIKI’s global standard in shaped knitting, the N.SVR® series, features a special model for producing Wholegarment® knitwear using every other needle. Shown in 21 gauge at DTG, N.SVR®183 is the ideal machine for flexible, entry-level Wholegarment® production of 12-gauge items. A conventional version of the N. SVR® series will also be shown in the form of the N.SVR®122 shaping machine in 14 gauge.

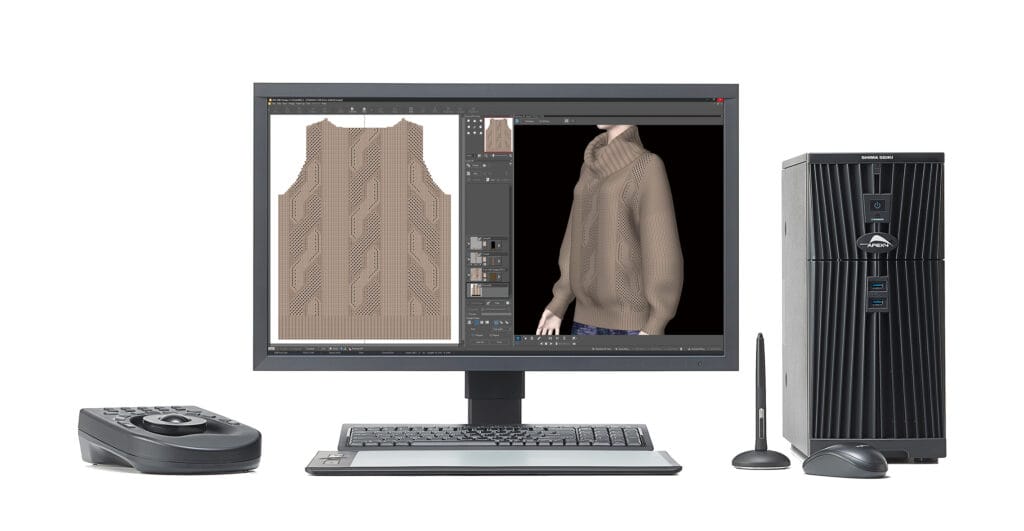

Demonstrations are available on Shima Seiki’s SDS®-ONE APEX4 3D design system, which supports the creative side of fashion from planning and design to colorway evaluation, realistic fabric simulation and 3D virtual sampling. Virtual samples are a digitized version of sample making that are accurate enough to be used effectively as prototypes, replacing physical sampling and consequently reducing time, cost and material that otherwise go to waste. When a design is approved for production, knitting data which is automatically generated can be converted easily to machine data, allowing smooth communication for digitally bridging the gap between design studio and factory. SDS®-ONE APEX4 help to realize sustainability while digitally transforming the fashion supply chain.

Demonstrations are available on Shima Seiki’s SDS®-ONE APEX4 3D design system, which supports the creative side of fashion from planning and design to colorway evaluation, realistic fabric simulation and 3D virtual sampling. Virtual samples are a digitized version of sample making that are accurate enough to be used effectively as prototypes, replacing physical sampling and consequently reducing time, cost and material that otherwise go to waste. When a design is approved for production, knitting data which is automatically generated can be converted easily to machine data, allowing smooth communication for digitally bridging the gap between design studio and factory. SDS®-ONE APEX4 help to realize sustainability while digitally transforming the fashion supply chain.