Leading computerized knitting machine manufacturer SHIMA SEIKI MFG., LTD. of Wakayama, Japan, together with its Turkish sales representative TETAS A.S., will participate in the 15th edition of CAITME Central Asian International Textile Machinery Exhibition in Tashkent, Uzbekistan this month. Much effort has been placed in the Uzbek textile industry to shift its industry from raw material supplier to garment exporter, and therefore its market offers new opportunities for development and implementation of new technology. To that end, SHIMA SEIKI will exhibit its latest flat knitting technology. On display will be the N.SSR®112 computerized flat knitting machine that offers leading technology in an economical yet reliable package. Featuring industry-leading innovations such as the R2CARRIAGE® that yields quicker carriage returns for greater efficiency, spring-type moveable sinker, DSCS® Digital Stitch Control System, stitch presser and takedown comb, Made-in-Japan quality, reliability and productivity, as well as user friendliness and cost-performance combine to satisfy the high expectations of the world’s fashion industry.

Leading computerized knitting machine manufacturer SHIMA SEIKI MFG., LTD. of Wakayama, Japan, together with its Turkish sales representative TETAS A.S., will participate in the 15th edition of CAITME Central Asian International Textile Machinery Exhibition in Tashkent, Uzbekistan this month. Much effort has been placed in the Uzbek textile industry to shift its industry from raw material supplier to garment exporter, and therefore its market offers new opportunities for development and implementation of new technology. To that end, SHIMA SEIKI will exhibit its latest flat knitting technology. On display will be the N.SSR®112 computerized flat knitting machine that offers leading technology in an economical yet reliable package. Featuring industry-leading innovations such as the R2CARRIAGE® that yields quicker carriage returns for greater efficiency, spring-type moveable sinker, DSCS® Digital Stitch Control System, stitch presser and takedown comb, Made-in-Japan quality, reliability and productivity, as well as user friendliness and cost-performance combine to satisfy the high expectations of the world’s fashion industry.

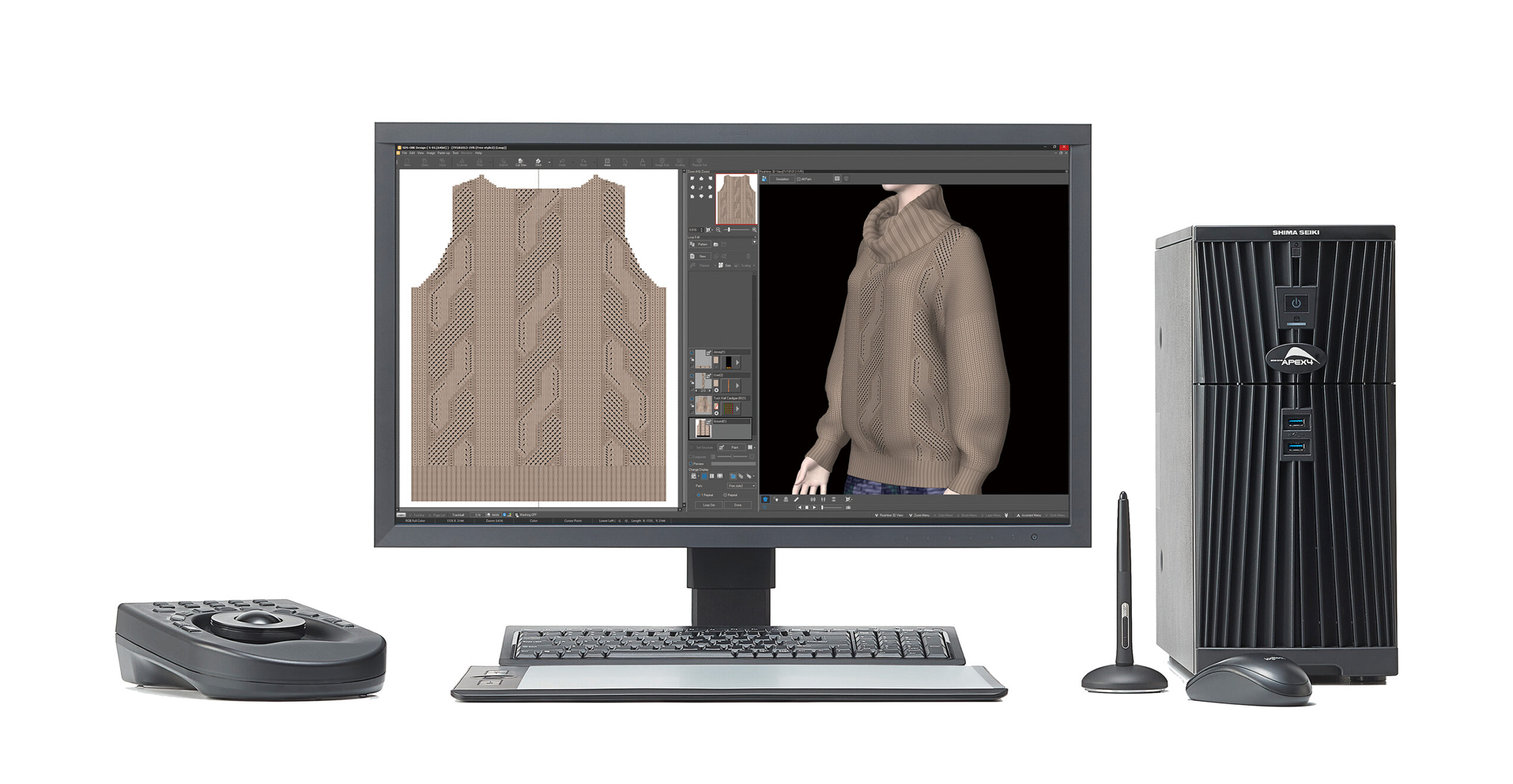

Demonstrations will be performed on SHIMA SEIKI’s SDS®-ONE APEX4 design system. At the core of the company’s “Total Fashion System” concept, SDS®-ONE APEX4 provides comprehensive support throughout the production supply chain, integrating production into one smooth and efficient workflow from yarn development, product planning and design, to production and even sales promotion. Especially effective is the way SDS®-ONE APEX4 improves on the design evaluation process with its ultra-realistic simulation capability, whereby virtual samples replace physical sampling, consequently reducing time, cost and material that otherwise go to waste. Digital prototyping using virtual samples on SDS®-ONE APEX4 help to digitally transform the fashion supply chain for realizing sustainable manufacturing.

Demonstrations will be performed on SHIMA SEIKI’s SDS®-ONE APEX4 design system. At the core of the company’s “Total Fashion System” concept, SDS®-ONE APEX4 provides comprehensive support throughout the production supply chain, integrating production into one smooth and efficient workflow from yarn development, product planning and design, to production and even sales promotion. Especially effective is the way SDS®-ONE APEX4 improves on the design evaluation process with its ultra-realistic simulation capability, whereby virtual samples replace physical sampling, consequently reducing time, cost and material that otherwise go to waste. Digital prototyping using virtual samples on SDS®-ONE APEX4 help to digitally transform the fashion supply chain for realizing sustainable manufacturing.