Shima Seiki USA Inc., the US subsidiary of leading Japanese flat knitting machine manufacturer Shima Seiki Mfg., Ltd., will hold the 3rd edition of its “Global 3D (G3D) Knitting Seminar & Workshop” at the Brooklyn Fashion + Design Accelerator in Brooklyn, New York, USA later this month. On display will be the cutting edge in computerised flat knitting technology, represented by the latest Wholegarment® knitting machines, computerised flat knitting machines, and 3D apparel design system.

With over 100 attendees and 50 companies participating at the previous edition, response toward past editions of G3D seminars and workshops has been highly positive. For the 3rd edition, Shima Seiki is now partnering with Brooklyn Fashion + Design Accelerator (BF+DA), an educational and professional resource for the fashion industry established by Pratt Institute that provides designers with the means to transform their ideas into a successful business. The purpose of the symposium is to bring together representatives from all across the apparel industry to focus on the future of the industry.

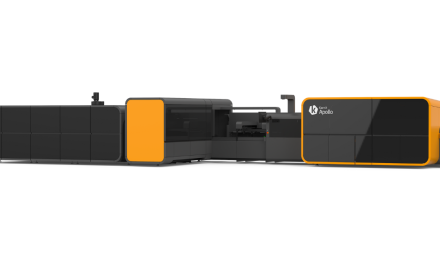

On display will be Shima Seiki’s flagship MACH2XS Wholegarment® knitting machine featuring the original SlideNeedle™ on four needle beds and spring type moveable sinkers. MACH2XS offers high efficiency and stability with extended patterning capability while knitting Wholegarment® items. The compact SWG061N2 Wholegarment® knitting machine offers flexible production as well as the capability for producing technical textiles for sports, medical and other industrial applications. The new SVR123SP computerised flat knitting machine features a loop presser bed with inlay capability, offering new and exciting possibilities in hybrid knit-weave textiles. The compact SSR112 workhorse machine will also be on display to demonstrate the leading edge in computerised shaped knitting technology.

The SDS-ONE APEX3 3D design system that is at the core of Shima Seiki’s “Total Fashion System” concept, which integrates knit production into one smooth and efficient workflow from planning and design to machine programming, production and even sales promotion. Virtual Sampling through photo realistic simulation minimizes the need for sample-making, effectively reducing time, material and cost from the sampling process. APEX3 also supports design and simulation in various other industries such as circular knitting, weaving, pile weaving and printing.