Sportswear is clothing worn while performing a sport or doing exercise. Almost all spotswear are made up of textile materials. Sportswear is also refereed as sport-specific clothing since they are worn while playing sports, or for any practical, comfort or safety reasons. Some of the sportswear includes shorts, tracksuits, T-shirts, swim suits, wet suits, ski suits, leotards, and are also worn as casual clothing.

Reactions while playing sports

Reactions while playing sports

- Move easily

- Get hot

- Get cold

- Sweat

- Sweat can lead to getting cold

- Get dirty

- Rubbing/chaffing

- Possible falls, knocks etc.

- Face rain, windy, sunny, snowy

- Day and night visibility

Requirements of a sportswear

Basically, a sportswear should have

- Optimum heat and moisture regulation

- Good air and water vapour permeability

- Rapid moisture absorption and conveyance capacity

- Absence of dampness

- Rapid drying to prevent catching cold

- Low water absorption of the layer of clothing just positioned to the skin

- Dimensionally stable even when wet

- Durable

- Easy care

- Lightweight

- Soft and pleasant touch

- Smart and functional design

There are two types of requirements for a sportswear. They are functional requirements and aesthetic requirements. The functional requirements for active sportswear require super lightweight, low fluid resistance, super high tenacity stretchablility whereas the aesthetic requirements includes view softness, surface texture, handle, lusture, colour & comfort.

Functional requirements

- The most important requirement of a sportswear is its light weight. The weight of the fabric should not affect the performance of the wearer, for instance, the sportswear used for cycling should not create wind drag or be too bulky

- On contrary, the sportswear should be loose for certain sports for like Karate in such a way that it does not restrict the movement of the wearer

- Moisture is transported in textiles through capillary action or wicking. The sports garment should transport moisture away from the skin to the garment’s outer surface. As removal of moisture is an important criteria, so is permeability of the fabric to rain water is important. For outdoor sports garments, it becomes a necessity

- For active sports, deodorizing socks and tops can be used in the form of antibacterial textiles which suppresses the growth of bacteria on the fabric which may be caused due to unpleasant odour

- Since sports are also performed in the outdoors, the requirement of the sportswear also includes being UV protective in such a way that it helps to reduce the impact of UV rays from reaching the skin

- Sportswear design must consider the thermal insulation needs of the wearer by providing the wearer to stay cool while in hot situations and to stay warm in old situations

- High active sportswear should also have high stretch and elastic recovery to provide sufficient fit and freedom of movement to the wearer

- In number of active sports like jumping, running and power lifting, compression is created by stretchable fabric to enhance the performance of an athlete. Compression athletic wear (CAW) provides the necessary compression and anatomic fit to an athlete. They are also known as “skin suits” as they conform to the natural curves of the body acting as second skin

- Sports textiles fabrics have a very high electrical conductivity, so they can permit the effectual dissipation of electrical charge

- Garments manufactured from sports textiles fabrics, keeps the normal stability of body comfort, because these fabrics are ultrabreathable, fast drying and possess outstanding moisture managing properties, which rapidly wick moisture away from the body

- These garments are also very less in weight & feature elasticity properties, which provides immense comfort and independence of movement

- Keeping a normal level of bacteria on the skin offers a high level of comfort and personal hygiene, especially during athletic activities

- Sports textiles fabrics remove UVA and UVB rays that are dangerous to the skin, and guarantees an improved level of defence compared to the majority general natural and manmade fibres

- It also provides superior strength and durability

- The athletics & the leisure activities for their better performance in the sports

Materials used for sportswear

Fibres used

Polyester

- Abrasion resistant – durable and hardwearing

- Non Absorbent – Doesn’t soak up sweat but is resistant to rain

- Crease resistant – Reduces ironing, good for clothes in sports bag

- Reasonable insulator – keeps heat in quite well

- Moth and mildew resistant – won’t rot if left damp

- Resistant to acids – sweat is an acid

- Collects static – not good if rubbing against other fabrics

- Strong

Nylon (Polyamide)

Nylon (Polyamide)

- Strong

- Elastic so stretches

- Does not absorb water

- Crease resistant

- Durable – hardwearing

- Not very warm to wear

Cotton

- Strong

- Not very elastic so doesn’t stretch

- Absorbent –soaks up water

- Creases easily

- Durable

Lycra / Elastane

- Very elastic so stretches well

- Crease resistant

- Durable so hardwearing

- Medium strength

- Not very absorbent so doesn’t soak up sweat

- Usually combined with other fibres to make a stretchy, form fitting fabric

Fabrics used

Entrant Dermizax EV

- Lightweight fabric having a feather smooth texture with excellent waterproof/moisture permeability and durable water repellence such as 20,000 mm of water pressure resistance and moisture permeability of 30,000 g/m2 /24 hrs

- Excellent and original active sportswear fabric with globally top class water proof/moisture permeability, as well as excellently durable water repellency

Entrant HB

- Hybrid structure that synergistically integrates the advantages offered by a coating and lamination

- It has high resistance to water pressure and high durability against repeated washings

Torray

- Made up of polyester micro fibre fabric with a unique highdensity weave structure comprising millions of micro crimped fibre loops

- It also features superb and durable water repellency, superior breathability and wind-chill resistance and attractiveness with soft hand

Naiva 30

- Naiva is an Eval/nylon bicomponent filament yarn and Eval is nothing but a copolymer resin of ethylenevinylalcohol

- In the Naiva fabrics there are many nylon micro loops on the surface, which are formed by making use of high thermal shrinkage property of Naiva yarn

- Naiva fabric not only has good moisture permeability but also has some other positive features like lightweight, softness and has capability of secondary finishing. The fabric is very successfully used in mountaineering wear and other active sportswear

Field sensor

- Field Sensor is a very popular high-performance fabric from Toray, which employs a multilayer structure that not only absorbs perspiration quickly but also transports it up to the outer layer of fabric very rapidly using principle of capillary action

- It is composed of coarser denier yarn on the inside surface and fine denier hydrophobic polyester yarn in a mesh construction on the outer surface to accelerate quick evaporation of sweat

COOLMAX®

- DuPont COOLMAX® is a high-performance fabric that can help the athletic performance of the people who wear it

- COOLMAX® moves sweat away from the body to the outer layer of the fabric, where it dries faster than any other fabric

- In moisture management tests, garments made with COOLMAX® dried almost completely in 30 minutes

Technological textiles used

Goretex

- Durably waterproof

- Very breathable

- Highly cold resistant

- Extremely light

- Resistant to flexing

Thinsulate Insulation

Thinsulate Insulation

- Thinsulate insulation Type G is comprised of 100 per cent polyester fibre

- Exceptionally soft and luxurious

- Traps and holds body heat for superior warmth

- Effective even when damp and after repeated washings

- Fibres absorb less than 1 per cent of their weight in water and dry easily

- Breathable

Polartec® Classic®

It is a very breathable, quick drying and non-pill fleece material. Wearing a Polartec® Classic® fleece underneath your waterproof enhances the breathability of the garment.

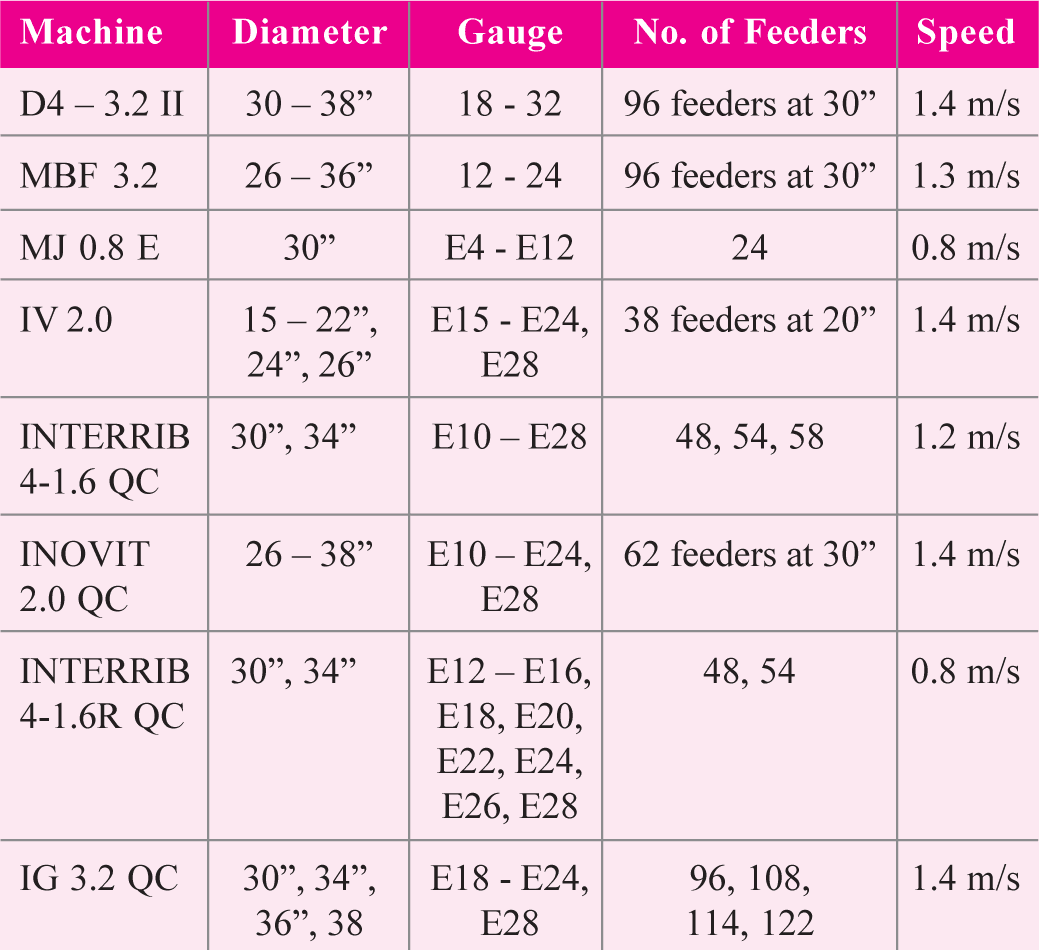

Machinery used for sports garments

The following machines from Mayer & Cie. are recommended for the production of sportswear garments

Production technology for sportswear

The principle feature of sportswear made from knitted fabric is that the nature of the final garment and the processing it goes through are affected in a major way by the primary knitting process. Since sportswear includes all types of apparel, it is possible to be produced by four differing processes. They are fully cut, cut-stitch shaped, fully fashioned and integral garment.

Fully cut:

Circular knitting of fabric −& couring, bleaching and dyeing −& Pressing, calendaring or stentering −& Fabric spreading −& Marking and cutting −& Assembly −& Examine and mend −& Finish press

Cut stitch shaped:

Flat or circular knitting of blanks −& Rough press −& Cutting −& Assembly −& Examine and mend −& Finish press

Fully fashioned

Knitting ribs and garment portions −> Rough assembly −> Scour, dye, finish −> Press −> Fabric cutting −& Examine and mend −& Finish press −&

Seamless or integral garment

Knit half hose −& Seam toes −& Wet finish, scour, dye −& Examine and mend −& Finish press, set

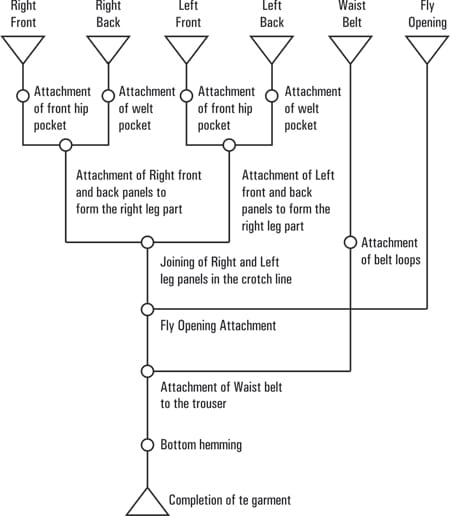

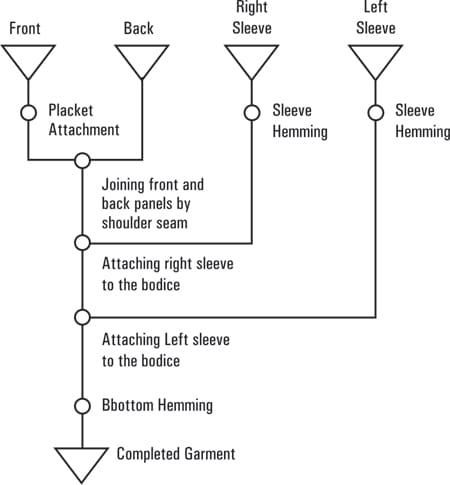

Operation Sequence for Sportswear– Garments for Upper Torso (T – Shirt) and Lower Torso (Trouser)

Conclusion

It is very important to design a sports garment based on the requirement of the respective sports activity. In this regard, this paper discussed the requirements of sports apparels such as a T-Shirt and a trouser with details of fibre requirements, machinery, operation sequence, and production technology for a sportswear were discussed. This paper will be useful to the academic/ industry that are planning to produce sportswear products.

AS Aishwarya Anand, PAnjana Priya, G. Ramakrishnan,

JSrinivasan- 1PG Scholars, Department of Fashion

technology, Master of Apparel Technology;2 Professor

Department of Fashion Technology, & Coordinator,

KCT-TIFAC CORE; 3Professor & Head, Department

of Fashion Technology, Kumaraguru College of

Technology, Coimbatore.

Reactions while playing sports

Reactions while playing sports