Cupro is the gentle fibre-a pure cellulosic fibre, reborn from the linter of the cotton plant. Cupro fibre is also known as Asahi Bemberg™, which is the name of the firm that firstly invented and put it on the market. Cupro is a filament similar to viscose in its characteristics, but, unlike viscose, it is lot finer and softer and it is more resistant to wetness and it does not buy any electric charge. Cupro fibres are also breathable, hygroscopic and it is proof against hyperhidrosis and salt water.

The origins of Asahi BembergTM date back to the late 19th century. In 1897, German company JP Bemberg succeeded in commercialising a new textile production technology called the cuprammonium process. In 1928, this technology was introduced into Asahi Kasei from JP Bemberg. In 1931, it built the Asahi Bemberg™ Plant in Nobeoka City, Miyazaki Prefecture, and started operations. Asahi Kasei has worked to improve the quality of Asahi Bemberg™ and expand its applications through the years, all the while giving our foremost consideration to the natural environment. The company has stood the test of time for over eight decades. Its quality is welcomed across the globe, and it continues to grow and ensure the comfort of human lives and the environment.

“We at Asahi Kasei have an unwavering wish to always think from the perspective of the customer and continue to create new values that had not existed before. We strive for harmony with the natural environment and ensure safety in our products and business operations. Our Asahi Bemberg™ Business is gentle on people and the environment. Asahi Bemberg™ is produced from a part of cotton that would ordinarily be discarded. Without wasting precious limited resources, combining natural materials with our unique technology, we will keep on creating new products that fit the times,” says Takeshi Iitaka, Manager, Asahi Kasei Corporation.

Born from cotton, better than cotton

Made from cotton linter

“Many people are familiar with cotton and the cotton plant. But perhaps few are aware of cotton linter, the fibre used to make Asahi Bemberg™. Cotton linter is the short, downy fibre that enfolds cotton seeds. It all starts with the gathering of this cotton linter around the tiny seeds. We import cotton linter from India to Japan to spun into yarn. So, only seed is used from cotton flower and nothing is wasted. So far our Japanese company is the only company in Germany, Italy, India producing this fibre,” says Takeshi Iitaka.

A pure cellulose fibre

The cotton linter is removed of all impurities and reborn as pure cellulose. It is then ready to be spun into yarn. Combined with chemical processing science and technology, the yarn acquires properties that cotton doesn’t have a softer and smoother touch to the skin.

Why better than cotton?

Because Asahi Bemberg™ originates in the natural cotton plant and is reborn with the infusion of human technology, it features both the gentleness of natural fibres and the functionality of manmade fibres. Each Asahi Bemberg™ fibre is extremely fine and has round cross section, largely free from the unevenness of natural fibres, and uniform in thickness. One touch, and the difference is clear – Asahi Bemberg™is softer than cotton.

- Fibre cross section:It is a near perfect circle in cross section, and has a more uniform thickness than cotton. This gives Asahi Bemberg™ a smooth, beautiful luster

- Crystal structure: Both Asahi Bemberg™ and cotton contain crystalline and amorphous regions. But Asahi Bemberg™ has a broader amorphous region, which absorbs and retains moisture

- Staple and Filament: In contrast to cotton, which is a staple fibre, Asahi Bemberg™ can produce both staple and filament fibres for a wide range of applications

Some major highlights

Feels silky smooth against the skin

“Asahi Bemberg™ has a near circular cross section and a smooth surface. It is also more uniform in thickness than other natural fibres. The fibre feels gentler to the skin than silk, considered by many to be a soft and low irritating material. Apart from having good feel this fabric is skin friendly also, so can be used in innerwear segment also. Famous Japanese innerwear brand UNICRO has selected our fibres for making their products. CUPRO fibre absorbs the moisture so very comfortable to wear,” says Takeshi Iitaka.

Takeshi Iitaka, Manager Asahi Kasei Corporation </span

At present, biggest market world over for Asahi BembergTM is India, with more than 30 per cent of our product being exported here.

Now, we are trying to enlarge our business in wide applications of home textiles, menswear in India as until now we were concentrating on ladies dresses like dupatta, sarees, salwar kamiz etc. only.

Akihiro Anguri, Senior Manager – Business Development – Fibres, Asahi Kasei India Pvt. Ltd.

We are targeting to increase our share manifolds in next few years in India, which is the reason for us having very aggressive marketing strategy for the market.

For last one year we are regularly participating in all major trade platforms in India to create more awareness about Cupro fibre by presenting latest apparel collections made out of the same.

Abrasion and skin irritation (standardization values)

Absorbs moisture and releases it into the air

Through the course of everyday life, our bodies produce a large amount of moisture. The skin secretes as much as 600 cc, or 4 cups, of perspiration each day. Asahi BembergTM is a breathable fibre with micro pores that quickly absorb moisture and release it to the outside. Thus the fibre effectively reduces clinging and interior dampness.

- Volume of moisture absorption and release: Comparisons of the amount of moisture different fabrics absorb and release reveals this fibre’s superb functionality. The difference is clear particularly between Asahi BembergTM and synthetic fibres

- Fabric interior and exterior: Compared to polyester, it retains less moisture between the skin and the fabric. Perspiration passes through the fabric and escapes into the air.

Comfortable to wear all year round

Temperature has a significant on a garment’s comfort. In warm weather, a garment needs to feel cool. In cool weather, it needs to feel warm. One prominent features of Asahi BembergTM is its ability to moderate the temperature inside the garment. It feels cool in summer, warm in winter, and because it even reduces static buildup, Asahi BembergTM is comfortable to wear year round controlling.

Temperature has a significant on a garment’s comfort. In warm weather, a garment needs to feel cool. In cool weather, it needs to feel warm. One prominent features of Asahi BembergTM is its ability to moderate the temperature inside the garment. It feels cool in summer, warm in winter, and because it even reduces static buildup, Asahi BembergTM is comfortable to wear year round controlling.

Proof of high moisture retention

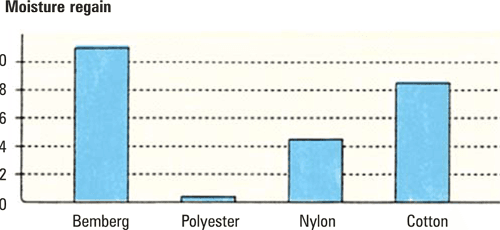

The graph compares standard moisture regain between different fabrics under normal conditions. It shows that Bemberg retainsthe largest amount of moisture.

Expanding range of applications

The fibre has a broad range of applications. Its gentle touch to the skin makes it ideal for linings, innerwear, and sportswear, its natural texture for adding a polished edge to outerwear. Hence it fits a variety of garments categories, from elegant to casual. The fibre is currently produced only in Japan, but its use is expanding into a growing number of fields around the world.

Mani Kant Ray, Director Bishnu Texport Pvt. Ltd. (Authorised dealer – Asahi BembergTM)

“We are associated with Asahi Kasei Corporation – Japan for more than 12 years for their ROICA brand spandex yarn. In 2014 our company got the opportunity to work for their premium product called Asahi Asahi BembergTM Yarn (Cupro Yarn) for untouched markets of textile producers in India. Asahi BembergTM has a dedicated team for Surat area and doing wonderful business for last 40 years.

At present Surat is biggest market and consuming around 450 tonne of per month of Cupro Yarn for producing fine quality of chiffon and georgette fabrics etc.

We started promoting Asahi BembergTM Yarn in different applications like shirting, suiting (Bottom wear), scarves, stalls and most prestigious market of sarees like Varanasi for Banarasi.

Growing share in Indian market

“The fibre’s properties are totally different from viscose fibre but application is almost the same. We make fibre yarn for application in ethnic clothing in India for sarees, dupattas etc. Our customers in India are very comfortable with silk but price of our product is half of the silk with almost same effect. Though mechanical properties are similar but the dyeing ability is different. It is very lightweight so our customers prefer to use yarns made of Cupro fibre,” said Akihiro Anguri, Senior Manager – Business Development – Fibres, Asahi Kasei India Pvt. Ltd.

He also adds, “At present, biggest market world over for Asahi BembergTM is India, with more than 30 per cent of our product being exported here. We began our journey with very small quantity but today it’s the biggest market for us. Now, we are trying to enlarge our business in wide applications of home textiles, menswear in India as until now we were concentrating on ladies dresses like dupatta, sarees, salwar kamiz etc. only”

Adding to this Takeshi Iitaka said, “We are targeting to increase our share manifolds in next few years in India, which is the reason for us having very aggressive marketing strategy for the market. For last one year we are regularly participating in all major trade platforms in India to create more awareness about Cupro fibre by presenting latest apparel collections made out of the same. Cupro yarns make refined, matchless materials with an exquisite and sensual, silk like touch. So, its precious softness and versatility makes it perfect for fashions, intimates, occasion wear and everyday athleisure wear”

sarees, West Bengal for Tanti sarees and South India for other sarees application, as we see a lot of scope in these segments. We have developed (by technical support from Asahi Kasei – Japan) yarn dyed of Cupro yarn in New Delhi and quality of yarn dyed has been approved by many of saree and fabric manufacturer in above mentioned markets. Currently, we have limited colors shade but will increase our colour shade basket as per customer demand. Especially, saree producer in Varanasi and West Bengal have good demand of dyed yarn to make traditional saree. As now pure silk price gone up and Cupro yarn dyed becoming better substitute for customer who likes silk touch fabric but lower price.

Working with Asahi Kasei group has always been very good experience and huge pride for me and my company. We always get complete support to promote Asahi BembergTM in India market. Asahi Kasei is the only producer of Cupro Yarn globally, which is a very premium in terms of brand image and quality. It holds very good reputation in India market especially among leading premium garments brands.

Bishnu Texport Pvt. Ltd. keeps stock of Asahi BembergTM (Cupro Yarn) in form of filament and staple fibre, in New Delhi to serve our customers easy and quickly. We also have arrangement to produce (Spinning) Spun Yarn made of Cupro staple fibre within India, and are also supplying spun yarn (100 per cent cupro) or with any blend of staple fibre from count range of 10s to 120s to suit in all application for weaving or knitting. Our company Bishnu Texport also has facility to supply Asahi BembergTM Yarn with Twisted (TPM). These are all made on order as per customer’s choice depending on their applications.