Polyester and polyester-rich blends are a popular choice for apparel, including sportswear and activewear. The challenge for manufacturers is to find ways to overcome the thorny issue of permastink byemploying either antimicrobial treatment or odor capture technologies. This article discusses the problem of odor control in polyester and polyester-rich blends, and describes a novel metal-free technology that can provide a more sustainable solution to address this concern.

Polyester and polyester-rich blends are a popular choice for apparel, including sportswear and activewear. The challenge for manufacturers is to find ways to overcome the thorny issue of permastink byemploying either antimicrobial treatment or odor capture technologies. This article discusses the problem of odor control in polyester and polyester-rich blends, and describes a novel metal-free technology that can provide a more sustainable solution to address this concern.

Introduction

Polyester is a popular choice in the global textile industry, with world production of this material exceeding that of all other fibers. It has numerous uses across various sectors, including hospitality, upholstery, and outdoor applications, and is particularly useful in the apparel industry. Man-made polyester fibers offer better durability, improved anti-shrinking and antiwrinkle properties, and greater resistance to environmental conditions, compared to their natural counterparts.

However, despite these clear advantages, odor control in polyester textiles still presents a challenge for the apparel sector. This is because these fabrics are in close contact with the microorganisms of the skin, as well as those present in the environment, and they show high adherence of bacteria and absorption of lipids – the primary nutrient source for bacteria– due to polyester’s greater hydrophobicity than natural materials. The warm and moist environment created by polyester then results in further growth of bacteria, many of which can cause unpleasant odors, stains, and fabric deterioration.

Odor control technologies

The degree of these malodors has been shown to be significantly higher in polyesters compared to cotton after the same exposure to sweat over an identical incubation period,1 and experiments have shown that laundering does not release odorants well. Repeated exposure to sweat increases the amount of odorant captured in the fiber, with malodor that cannot be effectively removed by conventional washing building up over time. This unpleasant odor, known as permastink, causes concern among consumers, and the textile industry needs to find a way to overcome this difficult issue.

There are two leading approaches for odor control technologies. Firstly, the direct control of odor generating bacteria on garments through treatments that can inhibit the growth of these microbes. Secondly, odorants can be neutralized or trapped by physical or chemical absorption, reducing their volatility and hence the smell on treated articles. Antimicrobial treatment of textiles, while an effective and straight forward solution, is subject to strict regulatory controls as well as technical challenges such as fiber compatibility and moisture management requirements. As a result, odor capture technologies have been growing in popularity.

Traditional odor capture technologies rely on absorbents such as activated carbon, cyclodextrins, and zeolites, but these are not always suitable for fabrics. Activated carbon, for example, is a powerful absorbent because of a tremendous number of surface pores that enable the absorption of a wide breadth of odors. However, its dark color makes it an unrealistic choice for use within a textile formulation. Similarly, cyclodextrins form a durable bond with cotton but have less affinity for, and durability on, polyester. Naturally occurring zeolites then might be an appealing choice from the sustainability perspective, but have little to no affinity for both synthetic and natural fibers, resulting in poor wash durability.

A sustainable metal-free alternative

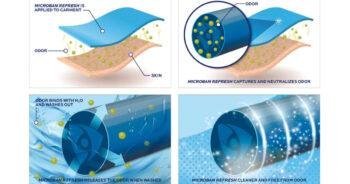

A more recent development is Refresh™, a patent-pending, metalfree odor capture technology from Microban International. This single component system employs an alkaline aqueous emulsion of synergistic polymers to neutralize acidic odorants – such as the carboxylic acids responsible for body odors – and can withstand extended wash cycles, for long-lasting effectiveness. It can be diluted with water and applied to the pad-and-cure process for incorporation into polyester fabrics during manufacture, providing a mill friendly, particle-free and durable odor capture solution that avoids concerns of roller build-up or complex recipes. Garments produced using material treated with this technology stay fresh; odors arising during wear are captured and neutralized before washing. The odorant is then released during washing, regenerating the fabric’s odor capture properties ready for the next time the garment is worn (Figure 1).

A more recent development is Refresh™, a patent-pending, metalfree odor capture technology from Microban International. This single component system employs an alkaline aqueous emulsion of synergistic polymers to neutralize acidic odorants – such as the carboxylic acids responsible for body odors – and can withstand extended wash cycles, for long-lasting effectiveness. It can be diluted with water and applied to the pad-and-cure process for incorporation into polyester fabrics during manufacture, providing a mill friendly, particle-free and durable odor capture solution that avoids concerns of roller build-up or complex recipes. Garments produced using material treated with this technology stay fresh; odors arising during wear are captured and neutralized before washing. The odorant is then released during washing, regenerating the fabric’s odor capture properties ready for the next time the garment is worn (Figure 1).

Proving the point

The effectiveness of this odor capture technology on polyesterrich fabrics was evaluated through a series of textile mill scale trials. Both dark and light fabrics were padded with this technology – with low pH adjustment for light colors –and cured at 150°C for at least 45 seconds. The efficiency of odor capture was assessed before home laundering and after 30 wash cycles to confirm the durability of the treatment. Fabrics were washed in a high efficiency, front-loading machine using representative commercial detergent home laundering and following washing protocol AATCC LP 1. Tumble drying was then performed using a normal dry cycle. The capture efficacy of the treated articles for the odorants acetic acid and isovaleric acid was conducted according to ISO 17299-2 and ISO 17299- 3, respectively. In addition, color fastness, wet/dry crocking, absorbency, and vertical wicking were respectively evaluated following AATCC TM 61-2A, AATCC TM 8, AATCC TM 79, and AATCC TM 197-Option B protocols.

The effectiveness of this odor capture technology on polyesterrich fabrics was evaluated through a series of textile mill scale trials. Both dark and light fabrics were padded with this technology – with low pH adjustment for light colors –and cured at 150°C for at least 45 seconds. The efficiency of odor capture was assessed before home laundering and after 30 wash cycles to confirm the durability of the treatment. Fabrics were washed in a high efficiency, front-loading machine using representative commercial detergent home laundering and following washing protocol AATCC LP 1. Tumble drying was then performed using a normal dry cycle. The capture efficacy of the treated articles for the odorants acetic acid and isovaleric acid was conducted according to ISO 17299-2 and ISO 17299- 3, respectively. In addition, color fastness, wet/dry crocking, absorbency, and vertical wicking were respectively evaluated following AATCC TM 61-2A, AATCC TM 8, AATCC TM 79, and AATCC TM 197-Option B protocols.

Demonstrated effectiveness

The treated fabric showed exceptional efficiency for isovaleric acid, initially capturing up to 97 percent of this odorant. ISO 17299-2/3 requirements were still exceeded even after 30 home laundry cycles, with up to 93 percent of the odorant being captured (Figure 2). The treatment was also effective for acetic acid, capturing up to 93 percent of odorant prior to home laundering and up to75 percent after 30 washes, surpassing the ISO 17299-2 standard (Figure 2).

The treated fabric showed exceptional efficiency for isovaleric acid, initially capturing up to 97 percent of this odorant. ISO 17299-2/3 requirements were still exceeded even after 30 home laundry cycles, with up to 93 percent of the odorant being captured (Figure 2). The treatment was also effective for acetic acid, capturing up to 93 percent of odorant prior to home laundering and up to75 percent after 30 washes, surpassing the ISO 17299-2 standard (Figure 2).

The application of a fabric treatment can sometimes be detrimental to a material’s properties; colorfastness, hand, moisture management, and phenolic yellowing can all be significantly impacted. Reducing the pH of the pad bath helps to avoid yellowing of white fabrics during finishing, and treatments that can be applied over a wide pH range deliver the essential flexibility required to allow manufacturers to optimize fabric performance. In this study, the pad bath was adjusted to pH 5.5 with citric acid for treatment of white polyester, and remained stable throughout the trial. Crucially, the fabric’s odor reduction performance remained unchanged.

The colorfastness of treated black polyester was evaluated as this is known to be particularly challenging, even for highly skilled and experienced manufacturers. There was no impact on colorfastness during wet crocking – and very little on dry crocking – and little to no effect on dye migration during laundering. Validation of the wicking and absorbency properties of all fabrics post treatment showed that these were also unaffected.

Finally, the effect of treatment on the hand of the fabric was investigated. The feel of a garment, along with its visual aesthetic, are key to creating a good first impression on consumers, making the hand one of the most important aspects in apparel. The study showed that, even at the highest recommended dosage, the drape and smoothness remain consistent across treated and untreated fabrics.

Conclusion

The patent pending, metal-free technology described in this article offers a more sustainable solution for addressing the issue of odor control in polyester and polyester-rich fabrics. This easy to use, single component finishing system – which is pursuing Bluesign® and Okeo-Tex® certifications – is ideal for synthetic textiles that require durable, long-lasting odor control, notably sportswear and activewear.

Treated materials exceed the ISO 17299 standard for the capture of isovaleric and acetic acids, even after extensive home laundering, while maintaining their original physical properties. The metal- and particle-free, ready-to-use formulation allows for quick integration into standard finishing operations, giving textile manufacturers confidence that treated fabrics will provide long-lasting odor control without the regulatory restrictions that commonly apply to traditional antimicrobial solutions.