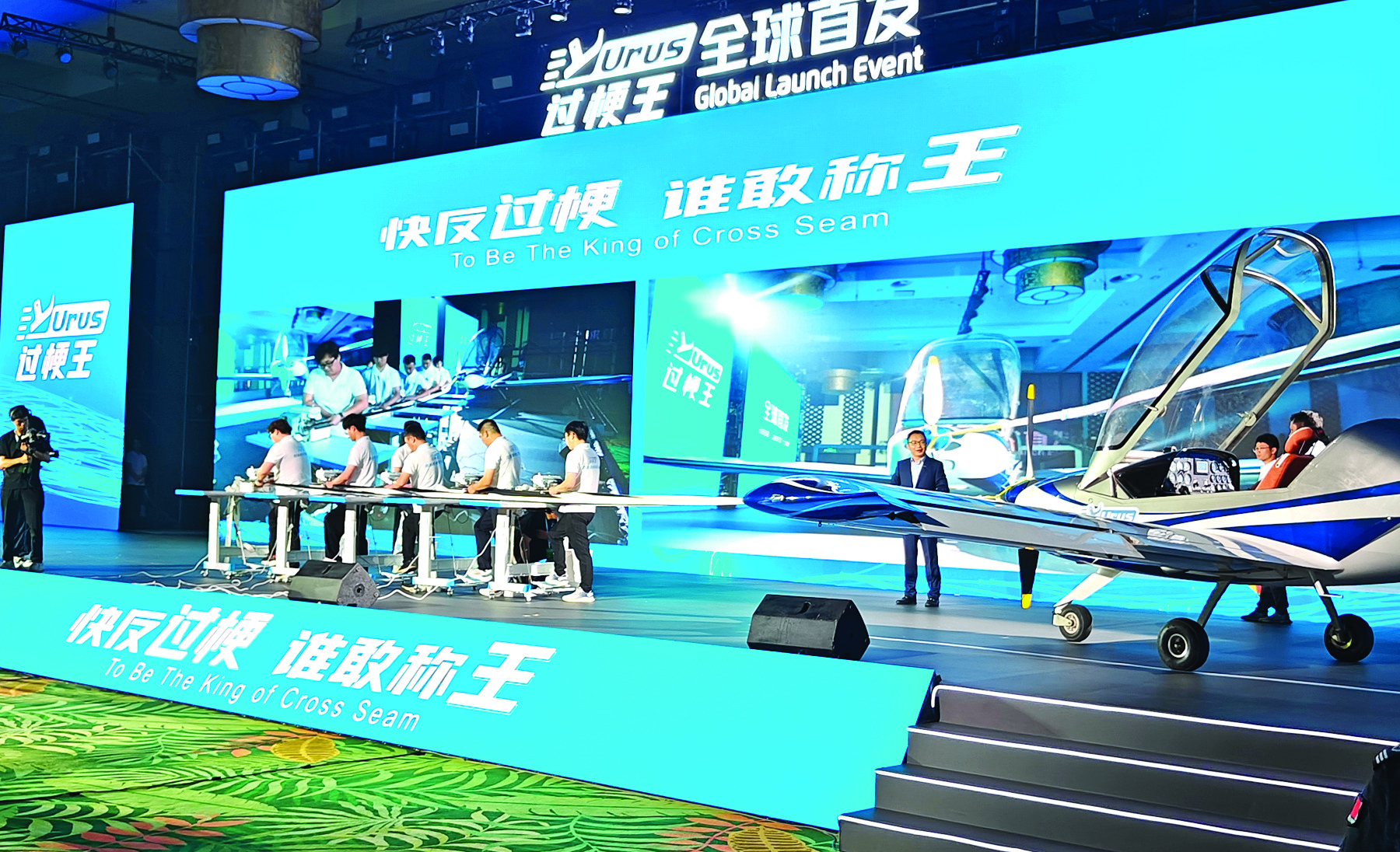

On June 16th 2024, Jack’s “To Be The King of Cross Seam”2024, Global New Product Launch Event was kicked off at Guangzhou Chimelong International Convention and Exhibition Center and a revolutionary new product was unveiled URUS. This revolutionary new sewing machine produced by Jack Technology, a top global sewing equipment manufacturer was displayed during the conference 2024 for worldwide distributors, customers and media over 30 sub-venues in China, Cambodia, Vietnam and other countries. URUS attracted attention of many specialists and scholars from the sewing industry. The Chairman of China Sewing Machinery Association, Vice President of China Garment Association, Tirupur Exporter Association, India, Bangladesh Garment Association and other leaders attended the conference to witness this milestone moment in the sewing equipment industry.

A New Chapter in Sewing with AI Power

A change towards a small orders and quick reorders paradigm has occurred in the sewing and textile industries due to the shorter fashion cycle and growing popularity of personalised clothes. However, problems such as machine stuck, fabric wrinkled, needles or threads broken always happened to traditional overlocks, especially when working on thick, thin, elastic, hard and other mixed fabrics.

For this industry, a new generation of overlock machines was desperately needed. In light of this, Jack Technology made the decision to incorporate artificial intelligence (AI) into sewing machines. It then formed close collaboration with eminent research institutions and universities around the world, such as Stanford University, the Chinese Academy of Sciences, Tsinghua University, and Zhejiang University. Jack spent four years solving these issues before launching the groundbreaking overlock machine, known as the URUS.

URUS is equipped with an industry-leading AI full-speed feeding system, a key technology that enables URUS to break through all joints of the thick fabric, elastic fabric, and denim hard fabric. Even if the thickness of different joints varies by hundreds of times, it can move smoothly at full speed without slowing down. URUS is also quite intelligent. At a rate of 32,000 times per second, the system could identify changes in fabric thickness intelligently using a model library of pressure-to-feed ratios. In case of slight change in fabric, it instantly calculates to generate the best pressing force and feeding force parameters.

After super brain completes calculating, two-core technology of URUS: Presser Foot Transformer and Smart Rhino Feeding will start to execute command based on the parameters. Presser Foot Transformer technology refers to the moment when the subtle changes in the fabric are sensed, the pressure transformation speed can be achieved by 0.00006 seconds, and the pressure distribution force can be adjusted immediately according to the different fluctuations of thick stems, thin stems, elastic stems, and hard stems; Smart Rhino feeding technology then accurately outputs the power distribution according to different fabrics, with an accuracy control of 0.01 Nm and a comprehensive torque of up to 9.2 Nm, achieving a perfect match between the pressure distribution force and the delivery force in real time.

Unmanned Sewing is the Future

On the same day in 2023, Jack Technology had launched their first sewing equipment product called AMH lockstitch. Since then, the product has sold over 500,000 units to global enterprises across more than 170 countries, accounting for 45% of the market.

However, Jack Technology always has a keen understanding for the growing challenges among clothing production all the time. In the near future, unmanned clothing production or automation will be the only way forward for the sewing equipment industry.

In view of the above challenges faced by the industry, Jack Technology announced that it will fully promote unmanned research and development, including deep integration of software and hardware with AI technology and gradually form unmanned production through the combination of various templates and humanoid robots, eventually staring a new era of intelligent production with AI technology implementation and practice.

In view of the above challenges faced by the industry, Jack Technology announced that it will fully promote unmanned research and development, including deep integration of software and hardware with AI technology and gradually form unmanned production through the combination of various templates and humanoid robots, eventually staring a new era of intelligent production with AI technology implementation and practice.

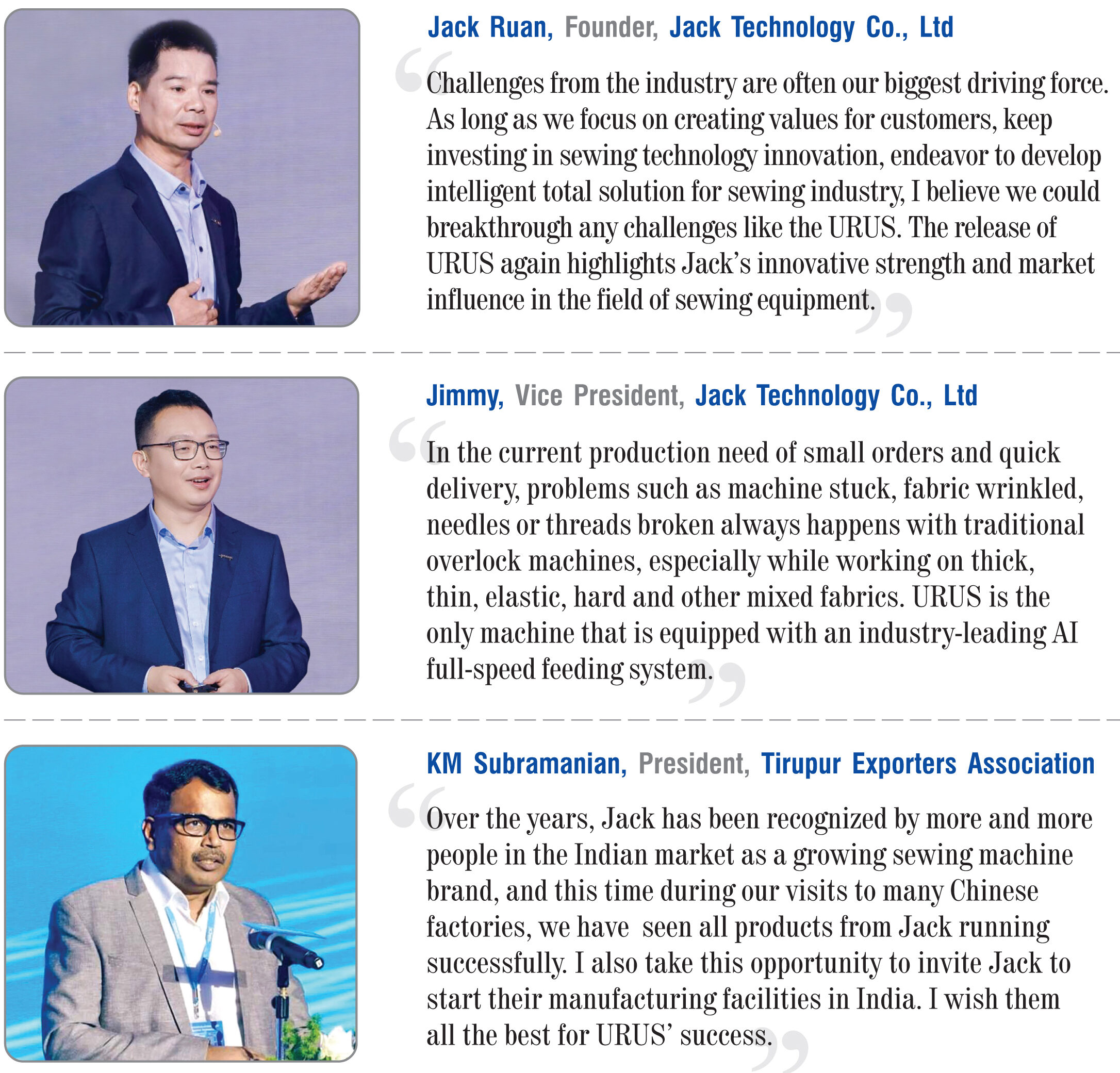

“Challenges from the industry are often our biggest driving force. As long as we focus on creating values for customers, keep investing in sewing technology innovation, endeavor to develop intelligent total solution for sewing industry, I believe that we could breakthrough any challenges like the URUS” said Jack Ruan, Founder, Jack Technology Co. Ltd.

He further explained the story behind the URUS to the guests. Since its establishment, Jack Technology has grown into a leading company in the world of sewing equipment, and the release of URUS once again highlights Jack Technology’s innovative strength and market influence in the field of sewing equipment. In the future, Jack technology will continue to promote the sustainable development and progress of the sewing equipment industry through AI technology, carry the banner of industry development, and inject new vitality into the clothing industry.

Mr. Jimmy, Vice President, Jack Technology Co. Ltd. formally introduced URUS to the audience and further informed them that “In the current production need of “small orders and quick delivery”, problems such as machine stuck, fabric wrinkled, needles or threads broken always happens with traditional overlock machines, especially while working on thick, thin, elastic, hard and other mixed fabrics. URUS is the only machine that is equipped with an industry-leading AI full-speed feeding system. With a million level pressure-to-feed ratio model library, the system could perform multimodal intelligent detection of fabric thickness changes at a speed of 32,000 times per second. Once the fabric changes slightly, it immediately calculates to generate the best pressing force and feeding force parameters”.

He further added “URUS has two core technology called Presser Foot Transformer and Smart Rhino Feeding and will start to execute command based on the parameters. The pressure distribution force can be adjusted immediately according to the fabric thickness. Smart Rhino feeding technology then accurately outputs the power distribution according to different fabrics, with an accuracy control of 0.01 Nm and a comprehensive torque of up to 9.2 Nm, achieving a perfect match between the pressure distribution force and the delivery force in real time”.

He further added “URUS has two core technology called Presser Foot Transformer and Smart Rhino Feeding and will start to execute command based on the parameters. The pressure distribution force can be adjusted immediately according to the fabric thickness. Smart Rhino feeding technology then accurately outputs the power distribution according to different fabrics, with an accuracy control of 0.01 Nm and a comprehensive torque of up to 9.2 Nm, achieving a perfect match between the pressure distribution force and the delivery force in real time”.

The chairman of China Sewing Machinery Association, Mr. Sun said “Jack has made products with ingenuity and successfully created the ultimate single product such as AMH, which not only ranks first in the industry in patent applications since 2013, but also ranks first in the industry in global sales and sales. Jack’s introduction of the URUS product is a useful attempt to realize intelligent manufacturing based on digital upgrades. I hope Jack can aim high, adhere to the integrity and innovation, and achieve a splendid future”.

Mr. Du, Vice president of China National Garment Association, expressed warm congratulations on the global debut of Jack’s new product URUS on behalf of the China National Garment Association. He said that the AMH launched by Jack Technology last year and the URUS released today provide strong equipment support and technical support for small orders and quick reorders and flexible intelligent manufacturing of clothing enterprises, and play an important role in promoting the technological progress and high-quality development of the entire clothing industry”.

During the launch event Mr. KM Subramanian, President, Tirupur Exporters Association and Chairman of KM Knitwear Co. Ltd., said that “Over the years, Jack has been recognized by more and more people in the Indian market as a growing sewing machine brand, and this time during our visits to many Chinese factories, we have seen all products from Jack running successfully. I thank Jack for giving me this opportunity to attend the launch event of URUS. I also take this opportunity to invite Jack to start their manufacturing facilities in India. I wish them all the best for URUS success and I am sure that Jack will become No.1 sewing brand in the world”.

During the launch event Mr. KM Subramanian, President, Tirupur Exporters Association and Chairman of KM Knitwear Co. Ltd., said that “Over the years, Jack has been recognized by more and more people in the Indian market as a growing sewing machine brand, and this time during our visits to many Chinese factories, we have seen all products from Jack running successfully. I thank Jack for giving me this opportunity to attend the launch event of URUS. I also take this opportunity to invite Jack to start their manufacturing facilities in India. I wish them all the best for URUS success and I am sure that Jack will become No.1 sewing brand in the world”.

Subsequently, a series of live demonstrations such as racing” and cross-country on the scene won bursts of applause from the audience. Later, Jack Technology displayed URUS performance during the conference, which was well appreciated by the audience. The extreme challenge of URUS VS Aeroplane has completely conquered more than 1,000 guests in the presence and nearly 2 million global viewers online. On this occasion, Jack also signed a strategic cooperation with Biemlfdlkk and Skechers.

Since it’s founding in 1995, Jack Technology has expanded to become a multinational company with the highest volume of sales and production as well as the strongest overall position in the sewing machine market. More than 160 nations and regions worldwide profit from Jack Technology products, which are used in a variety of industries including apparel, footwear, luggage, furniture, leather goods, automotive and aviation. The introduction of URUS once again demonstrates Jack Technology’s capacity for innovation and market dominance in the sewing machine industry.