The way we create designs for garments has changed forever. Today, with the rise of AI-generated artwork, stunning full color, photorealistic graphics can be created in seconds. Tools like aRDiX.ai, Midjourney, Firefly, and custom-trained image models allow brands and creators to generate unique, intricate, and personalized t-shirt designs instantly.

Artwork generated in few seconds using aRDiX.ai

These artworks are bold, gradient-heavy, detailed, and full of color transitions—an absolute nightmare for traditional screen printing.

Where Traditional Screen Printing Falls Short

Screen printing has been the backbone of garment decoration for decades. But it was built for a different era—when designs were static, flat, and limited to 4–6 spot colors.

Here’s the challenge:

• Every additional color = another screen

• Gradients and photo-realism are nearly impossible to reproduce accurately

• Setup is labor-intensive and time-consuming

• Small or custom orders are economically unviable

As a result, printers often reject complex AI-generated designs, simplify them to fit production limitations, or spend hours preparing screens—just for one job. The process limits creativity and slows down business.

The Hybrid Digital Printing Advantage

Hybrid digital printing is designed for this new world of creativity. It combines:

• The strength of screen printing for underbase and special effects

• The flexibility of digital to print full-color, high-resolution designs without screen separations

This combination allows you to:

• Produce vibrant, detailed designs without sacrificing speed

• Minimize setup time and enable quick design changes

• Print short runs profitably

• Say yes to AI-generated and highly customized designs that standalone DTG and screen printing simply can’t handle

The Power of Value Addition—A Hybrid Exclusive

Here’s where hybrid gets even more exciting. Because it retains the screen unit, hybrid opens the door to special effect printing— something DTG cannot achieve.

You can integrate:

• Glitter • Discharge • Foil

• Crack • Puff • And more custom textures

Even the underbase can be tailored based on buyer or fabric preference:

• Use discharge inks for a softer hand feel

• Use white paste for more opacity and vibrancy

With hybrid, you’re not limited by ink types or fixed workflows. You’re in full control.

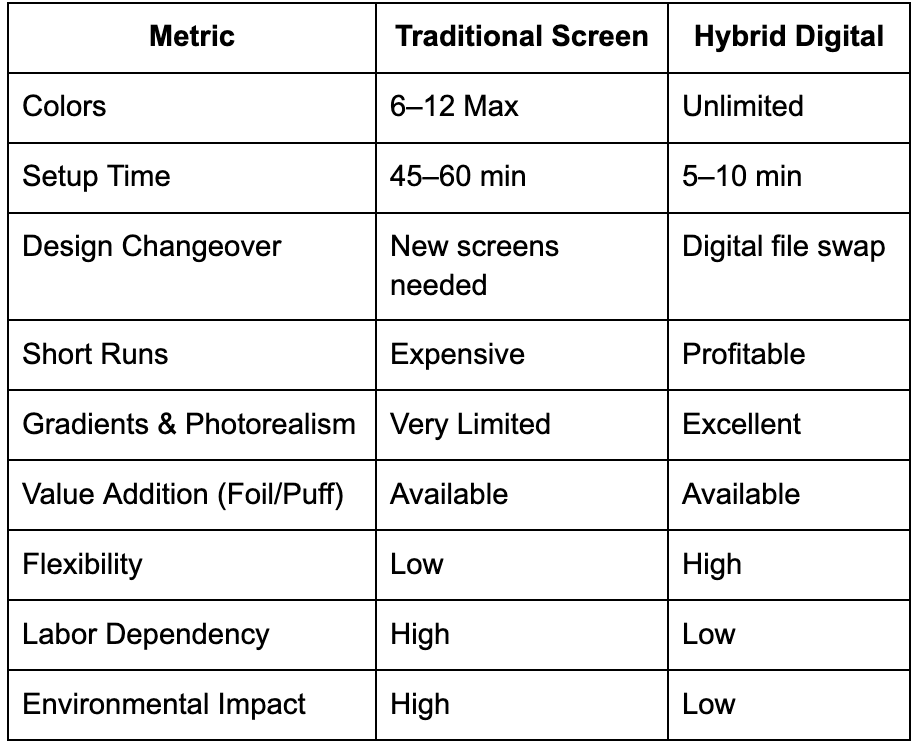

Screen vs Hybrid: By the Numbers

Why Hybrid Makes Business Sense

Why Hybrid Makes Business Sense

• Faster turnaround

• Higher-quality output

• Lower waste

• Fewer labor dependencies

• Freedom to accept more jobs and offer premium effects

• Adaptability for print-on-demand and personalized fashion models

It’s not just about efficiency—it’s about staying relevant in a market where clients want more, faster.

What We’re Doing at RDX

At RDX, we’re helping printers transition into this new era with intelligent hybrid systems:

• Smart Auto-Calibration: Aligns digital and screen layers automatically, reducing setup time and human error

• AI-Powered Defect Detection: Detects print issues in real time using vision systems

• Creative Automation Tools: AI-driven artwork generation for faster design-to-production cycles

• Hybrid Ecosystems: Machines built for value addition, scalability, and modern print workflows

We’re not building machines for the past. We’re engineering systems for the future of garment printing—designed, built, and led from India.

Conclusion: Print Should Empower Creativity, Not Limit It

The creative world has changed. Printing must catch up. Hybrid digital printing is not a trend. It’s a transition. From complexity to clarity. From constraints to creativity. And from screen-heavy limitations to smart, scalable production. If you’re building for the future—hybrid is how you get there

By Deepak Siddharth K, Founder at RDX Digital Technologies