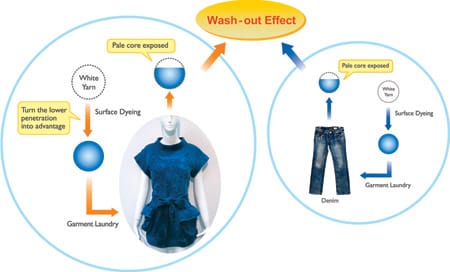

Clothes with vintage washing effect, such as jeans, have been well-received in the global market for over a hundred years. Recently, T-shirts with the same effect have become a new fashion trend. Market demand for this kind of product is huge.

Traditionally most of the cotton knitted fabrics are dyed in overflow dyeing machines with the dyestuffs completely penetrating through the fabric. Although some of the dyestuffs on the fabric can be removed during the garment washing process, most dyestuffs dyed into the inner part of the fibre will remain. As a result, a garment made from such fabric cannot achieve a wide colour variation.

Dyeing effect is different for the surface yarn-dyed denim. The inner parts of denim yarns cannot be dyed thoroughly and white cores exist within the yarns. They will be exposed after garment washing to create the vintage washing effect. At present, there is no successful surface dyeing method applying reactive dyes on cotton knitted fabrics to produce denim-like vintage T-shirts.

Features of the Novel Technology

This project examines the application of the foam technology to develop of surface dyed effect on cotton knitted fabrics with reactive dyes.

The foam technology with a lower pick-up ratio which is applied in textile processing, especially for finishing, has undergone rapid development since the 1980s. The technology consumes less energy during the drying process and leads to a lower production cost. However, due to its poor penetration and the resulting white core left inside dyed fabric, foam processing is not a common practice for dyeing.

This project has turned this shortcoming of the foam system into an advantage. In a different way from traditional liquid dyeing, dyestuffs distributed using the foam system is stable and light, with a low pick-up ratio of dye-foam on fabric. Therefore, the foam technology can create dyeing effect on single-sided fabric where the reactive dye-form is coated on one side of the fabric instead of full penetration. Since less dyes and chemicals are consumed during dyeing, the production process is better for the environment. Besides, it would improve the buildup property of dyes.

During the subsequent garment laundry process, parts of dyes on the fabrics surface are removed by enzyme-stone washing. Because of stronger mechanical action during laundry, the fading effect on the collar, cuff and hem of the garment would be more obvious than on other parts of the garment. The achieved contrast effect of colour depth on the surface of fabrics is the popular vintage wash. Besides, the application of reactive dyestuffs can extend the colour range and achieve brighter colours. Therefore garments made by this method will be more colourful and have better stereoscopic effects than conventional jeans. Compared with conventional dyeing for cotton knits, the foam surface dyeing technology can significantly simplify and shorten the dyeing process, lower water consumption as well as consume less dyestuffs and energy for drying.

Prospect of Industrial Application

There are thousands of dyeing and garment companies in Asia. Most of them are producing conventional products. This novel technology could be a new approach for the knitting garment industry to produce original and creative fabrics with higher value, and develop denim-like T-shirts. Successful industry trials have been conducted with satisfactory results, and it is expected that there is a good prospect for commercialisation.

Source: The Hong Kong Research Institute of Textiles and Apparel