Circular knitting machine builder Terrot is to close down its subsidiary Terrot Italy, formerly Pilotelli, and shift the production to its headquarters in Chemnitz, Germany. In a statement, Terrot’s Peter Schuring said the move was a result of the global drop in demand for circular knitting machines. “Due top the reduced worldwide demand for circular knitting machines, Terrot has decided to close its subsidiary in Italy, Terrot Italy S.r.l in Cazzago and to relocate its production completely to Terrot in Chemnitz,” he said. “The development and distribution of the machines was already integrated at Terrot, Chemnitz.

Circular knitting machine builder Terrot is to close down its subsidiary Terrot Italy, formerly Pilotelli, and shift the production to its headquarters in Chemnitz, Germany. In a statement, Terrot’s Peter Schuring said the move was a result of the global drop in demand for circular knitting machines. “Due top the reduced worldwide demand for circular knitting machines, Terrot has decided to close its subsidiary in Italy, Terrot Italy S.r.l in Cazzago and to relocate its production completely to Terrot in Chemnitz,” he said. “The development and distribution of the machines was already integrated at Terrot, Chemnitz.

Terrot acquired the then-troubled Italian manufacturer Pilotelli in 2014, which was involved in court proceedings related to insolvency at the end of 2013. The deal saw the formation of a new company, Terrot Italy Srl. At the time, for Pilotelli, the deal helped preserve the insolvent firm’s technological offering while opening up new areas to help it recover its business from the financial struggles it had experienced. For Terrot, the deal represented a major step in its on-going growth strategy.

“All of our customers will continue to be able to purchase all offered Pilotelli machines,” Schuring added. “The spare parts supply and service will be provided by Terrot Chemnitz. Delayed deliveries may occur during the first few weeks of the relocation. For this, we would like to apologies to our customers in advance.”

Pilotelli technology is known for its expertise in single-jersey and sinkerless knitting machines and, although well-established on a global scale, has been particularly strong in Turkey and South America.

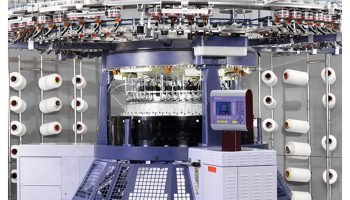

Among its latest developments is a new open-width circular knitting machine which, launched at last year’s ITMA exhibition, is described as one of the company’s highest ever production models. With 4 feeders per inch, the JV-4.0 OW operates at up to 45rpm on a 32 inch diameter machine giving it its high-speed factor of 1440.

According to Terrot, it was also important to ensure that ancillary equipment on the machine is geared towards meeting the stresses that are demanded by running at such high speeds. The result is that this new machine ensures less wear and tear by restricted needle movements due to newly designed sinker shapes, which minimizes the forces on needles and cams.

The single jersey machine is capable of knitting range of different structures including pique and offers a large pattern range with up to 4 needle tracks in the cylinder cam while also offering reliable and high quality elastane plating.

The JV-4.0 OW is available in a range of diameters from 26 – 34 ins with between 104 and 136 feeders (4.0 feeds per inch). Available gauges range from 20 to 34G. Different frame options are also available.

Circular knitting machine builder Terrot is to close down its subsidiary Terrot Italy, formerly Pilotelli, and shift the production to its headquarters in Chemnitz, Germany. In a statement, Terrot’s Peter Schuring said the move was a result of the global drop in demand for circular knitting machines. “Due top the reduced worldwide demand for circular knitting machines, Terrot has decided to close its subsidiary in Italy, Terrot Italy S.r.l in Cazzago and to relocate its production completely to Terrot in Chemnitz,” he said. “The development and distribution of the machines was already integrated at Terrot, Chemnitz.

Circular knitting machine builder Terrot is to close down its subsidiary Terrot Italy, formerly Pilotelli, and shift the production to its headquarters in Chemnitz, Germany. In a statement, Terrot’s Peter Schuring said the move was a result of the global drop in demand for circular knitting machines. “Due top the reduced worldwide demand for circular knitting machines, Terrot has decided to close its subsidiary in Italy, Terrot Italy S.r.l in Cazzago and to relocate its production completely to Terrot in Chemnitz,” he said. “The development and distribution of the machines was already integrated at Terrot, Chemnitz.