Shima Seiki, a leading flat knitting machine manufacturer of Wakayama, together with its UK subsidiary Shima Seiki Europe Ltd. will hold a Product & Sample Show at its offices in Derbyshire, England this month.With See More… Be More as its slogan, the exhibition encourages visitors to experience Shima Seiki technology to its fullest by showcasing a full array of textile machine technology.

Technology on display

The flagship MACH2XS series features Shima Seiki’s original SlideNeedle on four needle beds, as well as the patented springtype sinker system. The SWG-N2 series compact Wholegarment knitting machine is said to offer increased colour capacity, as well as the capability for producing industrial textiles.

The new SVR123SP machine features a loop presser bed and is capable of producing unique knit fabrics with woven textures as well as technical textiles, the company reports. The SSR112 machine features Shima Seiki benchmark technology in a compact, economical package. Also featured are SIP-series flatbed-type on-demand inkjet printing machines using reactiveand acid-dyes, as well as pigment ink (featuring new white pigment ink) and P-CAMcomputerised cutting machine.

Demonstrations

Demonstrations will also be performed on the SDS-ONE APEX3 design system that is at the core of the company’s Total Knitting System concept. With comprehensive support of the knit supply chain, APEX3 integrates knit production into one smooth and efficient workflow from planning and design to machine programming, production and even sales promotion.

“Photo-realistic simulation capability allows Virtual Sampling to minimise the need for actual sample-making, effectively reducing time, material and cost in the sampling process. APEX3 also supports design and simulation in various other industries such as circular knitting, weaving, pile weaving and printing,” the company reports.

Exhibit detail

Shima Seiki, a leading computerised knitting machine manufacturer of Wakayama, together with its US subsidiary Shima Seiki U.S.A. Inc., will participate in the Techtextil North America exhibition in Chicago, IL, this month.“Chicago’s proximity to Detroit, Indianapolis, and the rest of the Midwest where automotive, aerospace, biotechnology and various other high-tech industries strive, means the exhibition provides the opportunity to present Shima Seiki technology to these diverse innovation-driven sectors,” the company reports.

On display

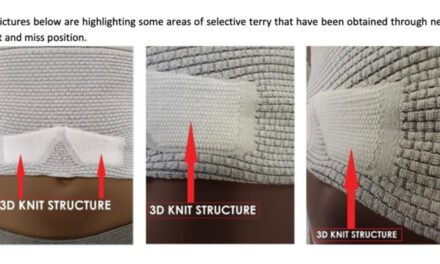

On display will be the company’s latest technological contributions aimed at promoting knitted applications in the field of technical textiles, designed and produced on Shima Seiki’s line-up of advanced computer design systems and computerised flat knitting machines.

Foremost attention is given to Wholegarment knitting which is designed to maximise the benefits of knitting in technical applications. Wholegarment knitting is capable of producing knitted items in their entirety on the machine, and allows complex 3D forms for fitting the human body or even car seats without the need for sewing, the manufacturer explains.

“Selective compression allows control over placement and amount of pressure for various compression wear in sports and medical applications. The seam-free nature of Wholegarment also ensures continuity of yarn, allowing functional yarns such as conductive yarns to wrap around the entire body for applications in smart garments and wearable technology,” the company reports.

MACH2XS

Demonstrating the latest in Wholegarment knitting technology at Techtextil will be the flagship MACH2XS machine that features the company’s original SlideNeedle on four needle beds and patented spring-loaded full-time sinker system.

Capable of Wholegarment knitting in all-needles, MACH2XS is said to offer great flexibility for knitting high-quality Wholegarment products with a seemingly endless variety of knit patterns at very high speed and efficiency, all while minimising dependence upon labour-intensive sewing and linking.

SDS-ONE APEX3

The latest version of Shima Seiki’s SDS-ONE APEX3 3D design system will also be available for demonstrations in design and simulation of various technical textiles. Of particular interest is its ultra-realistic simulation capability that realises Virtual Sampling, the manufacturer reports.

When countless variations must be evaluated before arriving at a final design, virtual product samples can be used to streamline the decision-making process by minimising the enormous amount of time and cost normally associated with producing actual samples for each variation.