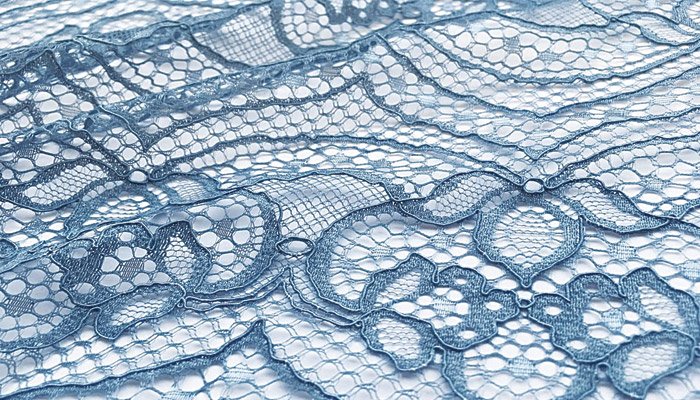

Warp knitting machine builder Karl Mayer has been demonstrating the flexibility of its latest raschel knitting technology. The OJ 59/1 B and OJ 83/1 B LACE.EXPRESS models are the latest technical innovations in jacquard multibar raschel machines from Karl Mayer. The pattern pictured here was developed in time for the ITM exhibition in April 2018 in Istanbul, which allowed the LACE.EXPRESS to demonstrate all its special features when processing bourdon cord.

The non-stretch, all-over lace is intended for use in apparel. Its decorative, scalloped edges can be used directly for the hems of dresses, skirts and tops. The scalloped design is continued into the lace fabric to create decorative, floral motifs in a striped arrangement. The flowers and leaves are interpreted graphically and arranged on a ground that is patterned with different designs. Karl Mayer also points out that narrow net patterns, organic structures and openpored holes create a dynamic design ensemble in the ground. The types of yarns used make the design appear to move. A combination of semi-matt, textured and shimmering yarns creates an eye-catching look with contrasting and surprising effects. Bourdon cord also creates a three-dimensional effect in the surface and is representative of a new trend. Liners with an embroidered look and 3D effects are still popular for fashion lace, but a high level of know-how and expertise are needed to produce them.

Polyamide yarns in a count of 1/40 f 9 were used for the pillar stitches and for incorporating the bourdon cords, which have a count of about 1,600 denier. The yarns were processed on an OJ 59/1 B in a gauge of E 24. The LACE.EXPRESS is also available in a gauge of E 18, so that it can also be used to process thicker types of bourdon cord. The first model of this machine series, the OJ 59/1 B, was only premiered at the end of 2016 and orders are already running into the high double-digit range. Up to 20 machines are leaving Karl Mayer’s assembly line for a number of projects, destined for a wide range of buyers including a mixture of new companies who are changing over from using machines produced by other manufacturer, and existing customers, many of whom are placing follow-up orders.

Encouraged by the first representative of the LACE.EXPRESS range, the Obertshausen-based firm has now extended this range of machines with the new model geared towards producing fabrics for outwear and underwear. This dual expansion was triggered by customer feedback on the OJ 59/1 B. The latest edition of the LACE.EXPRESS range has a working width of 210 ins, and can reach the same high operating speed as the OJ 59/1 B. However, increasing the number of guide bars compared to the first LACE.EXPRESS machine means that more patterns can now be produced. In particular, being able to work picot patterns also makes the new machine interesting for producers of tapes and ribbons for intimate apparel.