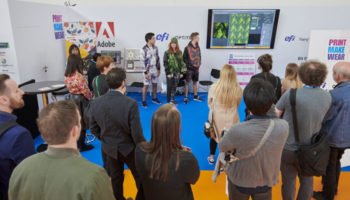

FESPA’s fast fashion factory feature, Print Make Wear, is set to return to FESPA Global Print Expo 2020 (24 – 27 March, IFEMA – Feria de Madrid), this time with a focus on sportswear production. Linking to FESPA’s new co-located event, Sportswear Pro, Print Make Wear will showcase the tools to facilitate customised, sustainable, on-demand production. The feature will recreate a live end-to-end production process for sports and athleisure garments, as well as hosting a series of tours led by FESPA’s textile ambassador, Debbie McKeegan.

FESPA’s fast fashion factory feature, Print Make Wear, is set to return to FESPA Global Print Expo 2020 (24 – 27 March, IFEMA – Feria de Madrid), this time with a focus on sportswear production. Linking to FESPA’s new co-located event, Sportswear Pro, Print Make Wear will showcase the tools to facilitate customised, sustainable, on-demand production. The feature will recreate a live end-to-end production process for sports and athleisure garments, as well as hosting a series of tours led by FESPA’s textile ambassador, Debbie McKeegan.

“Print Make Wear proved to be FESPA Global Print Expo 2019’s most attended feature and it’s not difficult to see why – it’s a vibrant forum where you can immerse yourself in all aspects of garment printing, from design to print and finishing,” says Debbie. “We want to give our visitors the opportunity to see first-hand how digital print technology, software and automation can revolutionise the production of sportswear and define potential new routes to market.”

As with past editions, Print Make Wear will address every step in the garment production process, starting with colour utilising CAD / CAM, design and prepress, production workflows, grading and nesting, progressing to printing, drying, cutting, sewing, welding and embellishment, culminating in packing and retail display. The feature will act as a physical link between FESPA Global Print Expo 2020 and Sportswear Pro 2020.

This year’s edition includes two workflows running side by side. The first one will exhibit direct-to-garment (DTG) printing onto blank sportswear and athleisure garments, where visitors will be able to order and customise a men’s running shirt or women’s racer back vest and leggings. The second workflow, dedicated to roll-to-roll printing, will replicate the whole garment production process from web-to-print to final delivery, with sample fabrics printed, cut, sewn and packaged on-site. The final printed samples will be displayed in a retail display and worn by models on the show floor. While Print Make Wear will convey the benefits of print on-demand and customisation in contemporary garment production, sustainability will also be a key area of focus.

“Sustainability is an essential component for future manufacturing technologies across multiple industries and the same goes for sportswear manufacturing,” Debbie explains. “As the key driver within our industry, sustainability will be heavily reflected across the whole of Print Make Wear. We’ll be highlighting how on-demand manufacturing helps significantly reduce waste. In addition, the majority of fabrics being printed onto are organic in source or recycled textiles and the physical elements of the feature build will be reutilised at future exhibitions.”

Further enhancing the visitor experience will be a comprehensive guided tour programme, making it easier for visitors to factor Print Make Wear into their busy event schedule. The tours will provide an in-depth look at all the components that go into DTG and roll-to-roll production, as well as highlighting how they can tackle customers’ requirements for on-demand customisation. Daily expert-guides tours can be booked in advance via the FESPA Global Print Expo 2020 website.

There will also be a series of ‘Experts in Conversation’ sessions that cover a range of topics, including:

• Best practice for colour management in apparel production

• Fashion technology and automation

• The positive impact of sustainable textile production

• The biggest challenges within sportswear production

Neil Felton, CEO of FESPA, concludes: “Sports apparel and fast fashion are two of the most dynamic growth applications in our textile printing community. Also, as evidenced by our research, a lot of the trends currently affecting sportswear manufacturing are reflected in specialty print. With this in mind, Print Make Wear is the perfect feature for showing our visitors the points in common between these two exciting industries. We’re confident that, whatever their level of knowledge or investment in garment printing, visitors to Print Make Wear in Madrid will gain a much deeper understanding of the opportunities for process improvement and differentiation.”