The name Terrot stands worldwide for quality and top performance in the production of electronic and mechanic controlled circular knitting machines. Innovations have a long tradition at Terrot. Its goal in the sector of Research and Development is to seize current market trends and to realize them as innovative products. Quality, a maximum degree of efficiency and a high cost-performance-ratio are always in the foreground at the development and the engineering of its machines. Its advantage through experience, technical know-how, expertise and commitment is shown by its everyday performance.

The name Terrot stands worldwide for quality and top performance in the production of electronic and mechanic controlled circular knitting machines. Innovations have a long tradition at Terrot. Its goal in the sector of Research and Development is to seize current market trends and to realize them as innovative products. Quality, a maximum degree of efficiency and a high cost-performance-ratio are always in the foreground at the development and the engineering of its machines. Its advantage through experience, technical know-how, expertise and commitment is shown by its everyday performance.

Quality is its highest priority since the beginning of the company history – as quality characterises a brand like Terrot. Its business success and therewith also the success of its customers is significantly affected by its performance. Therefore it always presents high-quality, extremely long-lasting and user-friendly solutions to the market.

Terrot is making future fabrics available today. With Corizon®, it offers a groundbreaking technology for reaching new horizons in our industry. All the sector of its industry has the opportunity to explore new roads to success if we pay careful attention to the world evolving around us. Wellinformed modern consumers in markets all over the globe are looking for textile goods that will improve their daily lives. This is not just about fashion in the sense of couture. The company is taking about new demands for uniqueness, boundary pushing and the inspiring exploration of functionalities. To meet these needs, fabric characteristics have to conquer new dimensions.

It provides a whole new spectrum of textile quality that will enhance your products across a variety of dimensions: The highest quality, unbelievable new degrees of softness, maximum strength and protection, high performance in durability or a core yarn that can create pure magic. All these possibilities are powered by a highly efficient and flexible production process that reflects the core values it believes in: The highest quality at a reasonable cost.

Whether you are looking for inspiration as a designer or new options as a textile brand or you are focusing on developing a flexible and faster production process that will save you more than just time and space, it allows user to discover what you can create with Corizon®.

Whether you are looking for inspiration as a designer or new options as a textile brand or you are focusing on developing a flexible and faster production process that will save you more than just time and space, it allows user to discover what you can create with Corizon®.

Textile champions at the core

Terrot has produced a technology that empowers textile manufactures and designers to create fabrics with remarkable features such as soft touch, great brilliance and even the strength to protect. As a fabric producer, you benefit from the time, space and material saving generated by a highly efficient production process.

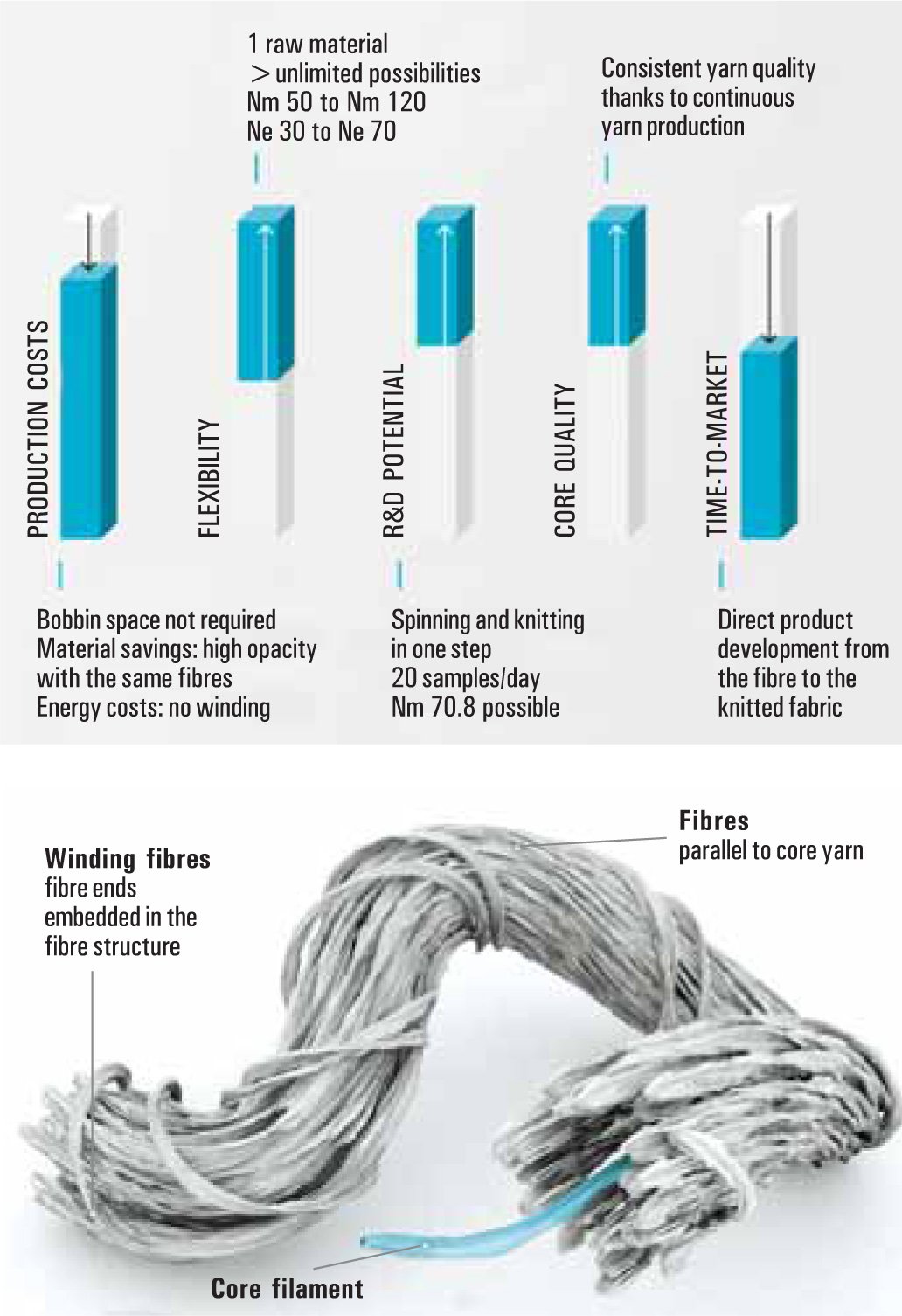

Innovative material structure

• Corizon® technology is a unique fusion process, made possible in essence by two things: German engineering and the power of air.

• Winding fibres: Fibre ends embedded in the fibre structure

• Fibres: Parallel to core yarn

• Core filament: It has created a technology that combines the knowledge of spinning and knitting in one revolutionary process. With Corizon®, one can generate a core yarn by combining a core filament that is surrounded by parallel fibres. Individual fibers are wound around the outside like a corkscrew. This structure generates sufficient strength and reliability to transport the yarn from the Corizon® system to any circular knitting machine.

Corizon® Data Sheet

Media

• Air pressure: Minimum 4.0 bar

• Air consumption: 18-29 I/min per spinning system

• Air quality: Classes 1-4

• Power consumption: 8KW

• Temperature: 24°C to 32°C / 75.2°F to 89.6°F

• Relative humidity: 35 per cent to 50 per cent adjustable

Machine specification

• 12 to 12 feeders

• Modular design expandable in increments of 12

• Fully electronic controls via touch panel

• Integrated monitoring process

• Integrated fluff removal

• Circular knitting machine also operable in jog or hand-drive mode

• Positive feeding device for solid and elastic* filaments

• Bobbin diameter up to 180mm, height up to 440mm

Types of knitting machines

• Plain single jersey machines

• Fine-rib and 2/1 rib machines

• Interlock machines

• Any brand and diameters up to 120 feeders

Production efficiency

• Delivery speed up to 200m/min

• Yarn range: Nm 50 / Ne 30-Nm 120/Ne 70

• 1raw material (1 roving count) for all yarn counts

Raw material specifications Roving

• Natural, synthetics and blends

• Staple fibres up to 40mm

• Cotton as combed fibre

• Roving count from Nm 1.5

Filament

• Continuous filament

• Plain or textured

• Solid & elastic 5-100 dtex

Corizon® Compact

• For all hosiery and small-diameter circular knitting machines

• 6 spinning systems, constant opacity across the entire product

• Positive yarn feed, completely even product

• Synchronous change of yarn count and loop length during ongoing operation