In current scenario, the consumption of the sportswear has been increasing tremendously. It is very important to produce sportswear with more comfort, functionality and cost effective. To obtain these, different fibres and techniques have been adopted to achieve the above properties. In this work, bi-layer knitted fabric has been produced in interlock jacquard knitting machine with inner layer as polyester and outer layer as cotton.The aim of this project is to develop polyester/ cotton bi-layer knitted fabric with different combinations and to study the physical aspects and comfort aspects such as wetting, wicking, water absorbency, dryness, moisture vapour transfer, thermal conductivity and air permeability based on objective and subjective evaluation. Based on the test results sportswear of combinations like 40s/150D, 40s/80D, 60s/150D, 60s/80D and 20s/150D are ranked. From this work it is recommended that bi-layer knitted fabrics can be used in sports like volleyball, athletics, cricket and foot ball for better comfort and performance of the sports person.

In recent times, there has been an increase in participation in active sports all over the world. The highly competitive world of sports has given rise to more number of professional sports people. They are much more conscious of the sportswear and demand more specific function to be performed by the sportswear. As a result new fibres and fabrics are emerging out for satisfying the stringent needs. Textile materials are used in all sportswear and in many games as sportswear. Examples of sportswear are: Aerobic clothing, athletic clothing, football clothing, cricket clothing, games shorts, pants, shirts, socks, sweat shirts, tennis clothing etc.

The human body has an operating temperature of 37°C, which it attempts to maintain under different circumstances. Due to the increased metabolism the body temperature rises during physical activity, such as participation in active sports, and the body created heat ranges between 100W at rest and 1000W during periods of intense physical activity. To maintain the body temperature 37°C during this intense physical activity it is necessary to transport the heat away from the body to the environment. The heat transport to the environment achieved through a dry flux (conduction, convection, and radiation) and a latent flux produced by perspiration. The cooling heat flow created by the perspiration is also transferred by conduction and convection. The dry flux depends on the insulation property of garments, while the latent flux depends on its moisture transport properties.

Moisture transport properties of textiles have great influence on the thermo-physiological comfort of the human body which is maintained by perspiring both in vapour and liquid form. The clothing to be worn should allow this perspiration to be transferred to the atmosphere in order to maintain the thermal balance of the body. Sports garments, particularly the layer worn next to skin, are key to the physiological comfort of an athlete, and their attributes in this aspect are critical to the athlete’s performance.

The performance requirements of many sports goods often demand widely different properties from their constituent fibres and fabrics, such as barrier to rain, snow, cold, heat and strength and at the same time these textiles must fulfill the consumer requirements of drape, comfort, fit and ease of movement. Among the contributing factors responsible for successful marketing of functional sportswear has been made in the fibre and polymer sciences and production techniques for obtaining sophisticated fibre, yarns and fabrics. The finishing and laminating industries have done pioneering work in the area of developing these technologies towards the needs of sportswear and sporting goods sectors resulting in unique products. This study aims to develop polyester/ cotton bilayer knitted fabric with different combinations and to study the physical aspects and comfort based on objective and subjective evaluation.

Materials and methods

Natural fibres such as cotton and wool are hygroscopic and are therefore characterised by high absorption levels. Unfortunately the absorbed moisture is bound in strongly and only released slowly. This results in low moisture transfer rate on textiles. On the other hand synthetics such as polyester, nylon and acrylics are not hygroscopic and therefore only absorb comparatively small amount of moisture. However surface of hydrophilic fibres have a high moisture transfer rate. Due to the above reason cotton and polyester has been selected as a raw material.

Selection of materials

The bi-layer knitted fabric with different combinations of cotton and polyester was produced. The selected combinations of cotton/ polyester were: 20s/340D, 20s/150D, 20s/80D, 40s/340D, 40s/150D, 40s/80D, 60s/340D, 60s/ 150D, and 60s/80D.

Fabric preparation

The fabric is constructed in an interlock jacquard knitting machine (Make-OVJA36) with 36 feeders and knitting speed of 15 rpm. With the necessary settings to produce the 6/8 bi-layer structure, the above combinations of fabric was knitted accordingly. The combinations consist of coarser, medium and finer counts in cotton and deniers in polyester. Cotton was the outer layer and was feed in cylinder needle whereas the polyester was fed in dial needles which were an inner layer that suits the concept of bi-layer.

Processing of polyester/cotton

The fabrics were bleached using hydrogen peroxide for 1 hour at 100°C to remove the natural colouring matters, impurities, dirt, grease etc. Then it is subjected to dyeing with hot brand reactive dye for 6 hours at 30°C in winch dyeing machine, followed by washing, drying and compacting.

Testing

Geometrical properties such as EPI, WPI, stitch length, stitch density and areal density (GSM) of the fabrics were determined as per standards. Abrasion resistance, drape co-efficient, stiffness, pilling and thickness of the fabric were also determined as per stipulated standards. Comfort properties such as wettability, wicking, water absorbency, drying rate, water vapour permeability, air permeability and thermal conductivity of the fabric samples were determined.

Wettability: Wettability is defined as the time in seconds for a drop of water or 50 per cent sugar solution to sink into fabric. Fabrics that give times exceeding 200s are considered unwettable. Wettability of the fabric samples was tested by using Electronic Tester developed by the authors as per British Standard (BS 4554 1974). Three specimens with five areas on each specimen were tested for each sample.

Wicking: In this test, a strip of fabric is suspended vertically with its lower edge in a reservoir of distilled water. The rate of rise of the leading edge of the water is then monitored. The measured height of rise in a given time is taken as a direct indication of the wickability of the test fabric. Five specimens were tested for each sample.

Water absorbency: Water absorbency is a quality of fabric to absorb water. It is a method for measuring the total amount of water that a fabric will absorb. In this test, a sample of size 20 cm x 20 cm was dipped in the solution for 5 minutes. Then it was hung vertically for 5 minutes and weighed. Percent gain in weight of fabric sample was taken as water absorbency of the fabric. Four specimens were tested for each sample.

Dryness: The evaporation rate is determined by drying the selected fabric samples for 30 minutes at 100° cither evaporation rate is expressed in terms of percentage of fabric weight reduction.

Dryness: The evaporation rate is determined by drying the selected fabric samples for 30 minutes at 100° cither evaporation rate is expressed in terms of percentage of fabric weight reduction.

Results and discussion

Geometrical Properties

Results of geometrical properties are given in Table 3.

In both sides of the bi-layer fabric, similar value of wales per inch and courses per inch is identified for the cotton as well as polyester in different combination. In loop length, there is slightly variation occurs between cotton and polyester based on the machine settings. Stitch density decreases from coarser count/ denier to finer count/denier. Tightness factor varies accordingly from coarser, medium and finer. Coarser combinations (with respect to cotton) has high tightness factor when compared to medium and finer combinations. GSM of the fabric will vary according to the count and denier of the cotton and polyester in different combinations.

Physical properties

Abrasion resistance

Results of abrasion resistance are shown in Figure 1.

Coarser denier polyester has no abrasion due to its rough and tubular structure. Medium and finer combinations (with respect to cotton) of cotton and polyester have similar and high weight loss percentage when compared to coarser count.

Drapeability: Results of drapeability are shown in Figure 2.

Drapeability: Results of drapeability are shown in Figure 2.

For medium and finer combinations (with respect to cotton), the drape coefficient percentage is low when compared to coarser combinations for both cotton and polyester. The drape coefficient percentages for all cotton/polyester sides are somewhat similar.

Stiffness: Results of stiffness are shown in Figure 3.

The bending rigidity of medium and finer combinations is low when compared to coarser combinations. The bending rigidity of course way and wales way varies for both cotton and polyester.

Pilling: Results of pilling are shown in Figure 4.

Pilling: Results of pilling are shown in Figure 4.

Cotton has very severe pilling whereas polyester has no pilling and has no much difference between deniers, due to its tubular structure and smooth surface. Finer count of cotton has varying pilling rate when compared to medium and coarser count.

Thickness: Thickness results are shown in Figure 5.

In coarser combinations the thickness is high, where the coarser denier and coarser count plays a major role. The thickness in denier and count from coarser to finer decreases. Higher the denier and lower the count has higher thickness. This is because of the differences in the construction and combination of yarns in the fabrics.

Comfort properties

Wetting (Sinking method)

The result found that synthetic material (polyester) sinks quickly than cotton due to tubular structure. In polyester the sinking time of coarser denier is high and low in finer denier. In cotton finer counts sinks quickly than coarser.

Wicking

Wick ability of the fabric is mainly depends upon the fabric construction, yarn regularity and type of fibre and its characteristics.

In polyester the capillary rise is higher due to its tubular structure which favours high wicking rate. Cotton doesn’t contribute much in wicking when compared to polyester. Overall, 40s combination shows best results when compared to coarser and finer. It’s an interesting phenomenon but still we have no reason.

Water absorbency

Water absorbency mainly depends upon the porosity of fabric and the type of fibre and yarn.

Polyester absorbs quickly than cotton, this is the special characteristics of bi-layer that is suitable for sportswear that performs well in sweat absorption.

Dryness

The drying rate of coarser combination is low when compared to medium and finer combinations. The finer combinations dry quickly due to its high porous nature and low GSM.

Moisture Vapours Transfer (ASTM 96 – Cup method)

Moisture Vapours Transfer (ASTM 96 – Cup method)

The medium and finer combinations (With respect to cotton) have high moisture vapour transfer due to its high porous nature. In coarser combinations the rate of moisture vapour transfer is low.

Thermal conductivity

In coarser combinations the conductivity is higher due to higher thickness of fabric. Thickness is directly proportional to thermal conductivity. Thermal conductivity varies according to the thickness of the fabric.

Air permeability

Air permeability

Air permeability of the fabric is similar on both sides. Finer combinations have higher permeation due to porous nature. Coarser combinations have very low permeation when compared to medium and finer.

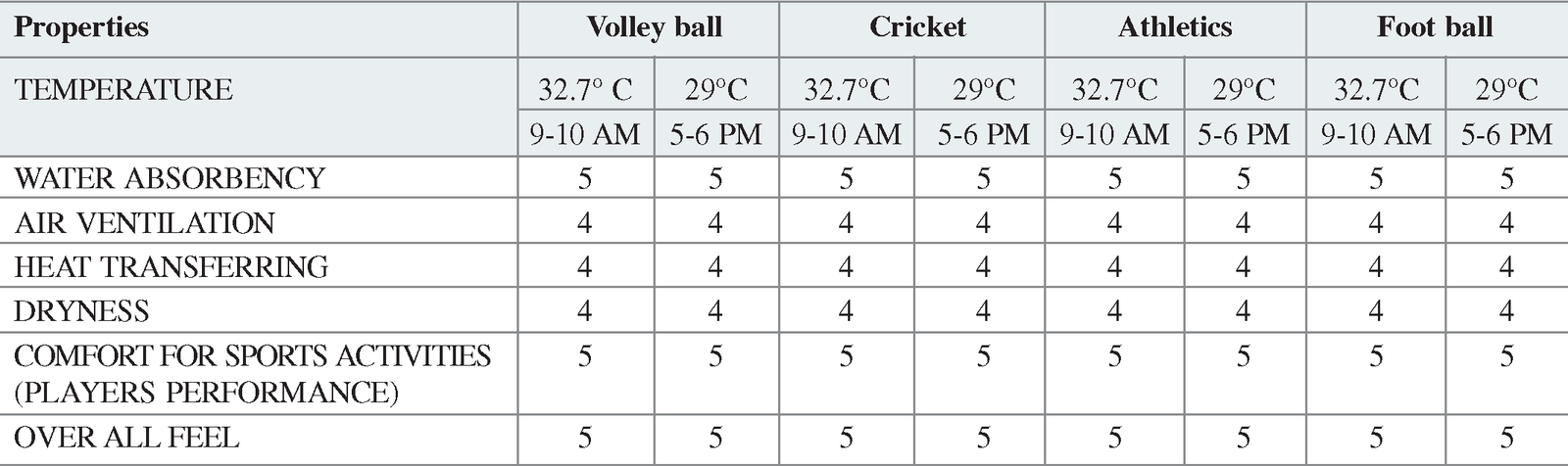

Wear study

The purpose of subjective evaluation is to know the suitability of sports activity with respect to the product design and climatic condition. The property such as absorbency, air permeability, heat transfer, dryness and feel has been chosen to study the subjective evaluation of different sport activities. The subjective evaluation is purely based on the psychological feeling of sports person which is rated within five scale rating.

The sportswear was given to sports person of athlete, volley ball, foot ball, and cricket. The wear study was conducted at different timings to know the comfort at different climatic conditions.

Table 4.1 Wear study Of C/P (20s cotton with 340d polyester) 6/8

Table 4.2 Wear study of C/P (20s cotton with 150d polyester) 6/8

Table 4.3 Wear study of C/P (40s cotton with 340 D polyester) 6/8

Table 4.4 Wear study of C/P (40s cotton with 150D polyester) 6/8

Table 4.5 Wear study of C/P (60s cotton with 150D polyester) 6/8

Table 4.6 Wear study of c/p (60s cotton with 80d polyester) 6/8

Conclusion

Based on objective and subjective evaluation the following conclusions have been made:

- Water absorbency for all the garments is found to be very good to excellent and absorbs the sweat quickly

- Air ventilation for all the garments for all the garments is found to be good to excellent and the range denotes that it permits air inside

- Heat transferring for all the garments is found to good to excellent and the range denotes that it dissipates the heat quickly

- Dryness rate for 20s/340d and 40s/340d is found to be fair and good in 20s/150d, whereas 40s/150d is very good and excellent in 60s/150d, 60s/80d

- The comfortness of the garments for 20s/340d is fair and 20s/ 150d, 40s/340d is found to be good, whereas 40s/150, 60s/ 150d, 60s/80d is found to be excellent

- The overall feel of the garment for 20s/340d is fair and 20s/ 150d, 40s/340d is found to be good, whereas in 40s/150d, 60s/150d, 60s/80d is excellent

The garments of combinations like 40s/150D, 40s/80D, 60s/ 150D, 60s/80D and 20s/150D are ranked accordingly as first, second and so on. Hence, it was recommended to be used in the active sports like volleyball, athletics, cricket and foot ball for better comfort and better performance of the sports person