Bi layer fabrics are used to ensure better clothing comfort in sports and active wears. High moisture transfer properties of these fabrics influence comfort properties and make them more functional. In this study, bi-layer knitted fabrics were developed with two types of yarns such as cotton (outer layer) and polypropylene (Inner layer) namely 20Ne/120D, 20Ne/240D, 40Ne/120D and 40Ne/240D combinations and their air, moisture and thermal transfer characteristics were studied. The comfort properties selected for testing and analysis were air permeability, thermal conductivity and moisture transmission properties such as moisture vapour transfer, wicking, wetting, water absorbency and drying. The sportswear was given to sports persons of volleyball, football, and basketball. Dampness, thermal and clammy sensations were studied and the ratings were analysed. The result of both subjective and objective testing indicates that the combination 40Ne/120D provides better comfort and can be preferred for active sportswear clothing for sports such as volleyball, basketball and football.

The active sportswear fabrics are designed for use in garments that provide protection from the environmental factors like wind, rain and loss of body heat. Active sportswear is a kind of sportswear which requires high moisture transfer properties than commercial sportswear. High functional fabrics support active sportswear with importance placed on high functions as well as comfort.

Sportswear textiles belong to a category called sport tech, which is one of the mainstream technical textiles. The consumption of textile fibres and fabrics in sportswear and sporting related goods has seen a significant increase in the last decade or so. The trend in consumption of sportswear reflects to a large extent the significant rise in interest of the population worldwide in active indoor and outdoor sports as well as in outdoor leisure pursuits.

In recent times, there has been an increase in participation in active sports all over the world. The highly competitive world of sports has given rise to more number of professional sports person. They are much more conscious of the sportswear and demand more specific function to be performed by the sportswear. As a result new fibres and fabrics are emerging out for satisfying the stringent needs.

The sports clothing of today have become technically oriented, using highly functional textiles for both casual and performance sportswear. Today textile manufacturers are developing their own signature products. Tremendous progress has been made in the development of fibres and fabrics for sportswear and those developments coming mainly in the areas of comfort or functionality and aesthetic acceptability. Sports garments, particularly the layer worn next to the skin, are key materials to the physiological comfort of an athlete, and their attributes in this aspect are critical to the athlete’s performance.

The human body has an operating temperature of 37°C, which it attempts to maintain under different circumstances. Due to the increased metabolism the body temperature rises during physical activity, such as participation in active sports, and the body-created heat ranges between 100W at rest and 1000W during periods of intense physical activity. To maintain the body temperature at 37°C during this intense physical activity it is necessary to transport the heat away from the body to environment. The heat transport to the environment is achieved through a dry flux (conduction, convection and radiation) and a latent flux produced by perspiration. Thus the body vapour and liquid sweat must have the opportunity to pass effectively from skin to the outer surface of the clothing.

The aim of this study is to develop a special double face knitted fabric that will achieve a high level of clothing comfort for sports and active wears. The characteristics of this special knitted structure are concerned with the existence of two different fabric surfaces. The inner surface is considered as the separation layer with a hydrophobic synthetic fibre, which was selected as polypropylene due to its high water transfer capillarity, lightweight and easy care properties. The outer surface is the absorption layer with a hydrophilic characteristic, in which cotton yarn was used due to its high moisture absorption property.

Materials and methods

Materials used

The following yarns were chosen to produce bi-layer knitted fabric

- Cotton- 20Ne and 40Ne Combed yarn

- Texturised Polypropylene-120 D and 240 D

Knitting construction

The prerequisites of ideal sportswear are rapid transport of perspiration away from the body and then its rapid evaporation to keep the fabric dry. This is achieved by bi-layer of fabric construction in which the inner layer is made of polypropylene filament yarn that is hydrophobic and has good wicking rate. The outer layer is made up of natural fibre such as cotton which has more absorption character and rapid evaporation. The fabric is constructed in an interlock knitting m/c with jacquard feature. The fabric which has to form as inner layer is fed in the dial needle and the outer layer is fed in the cylinder needle.

Machine parameters

Machine parameters

1. Type : Interlock Jacquard knitting machine

2. Make : Mayer & Cie – OVJA36

3. Feeders 1& 3 : Cotton

4. Feeders 2 & a 4 : Polypropylene

5. Gauge : 20 needles/inch

6. Diameter : 30 inches

7. Total needle count : 3744

9. No. of feeders : 36

10.Knitting speed : 15 rpm

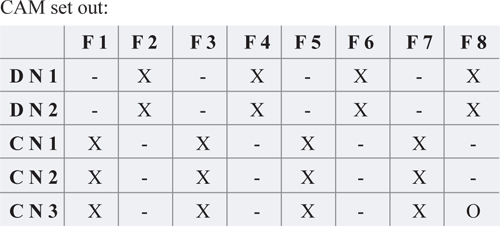

Concept of bi-layer fabric structure

Dial Needle: Two tracks (Polypropylene yarn)

Dial Needle: Two tracks (Polypropylene yarn)

D N 1 – Dial needle track 1 D N 2 – Track 2

N– Needle F – Feeder

A –Needles moving in track 1 – 1,3 ,5,7,9,11,13,15,17

B – Needles moving in track 2 – 2,4,6,8,10,12,14,16,18

Cylinder Needle: Three tracks (Cotton yarn)

C N 1 – Cylinder needle track 1

C N 2 –Track 2 C N 3 –Track 3

A –Needles moving in track 1 – 1,3,5,7,9,11,13,15,17

B – Needles moving in track 2 – 2,4,6,8,10,12,14,16,

C – Needle moving in track 3 – 18

–Miss Cam x –Knit Cam o –Tuck Cam

Feeder 1,3,5,7 …….. – Cotton

Feeder 2,4,6,8 ……….. – Polypropylene

Dial cam has two tracks of DN1 and DN2. The A and B needles are moving in track 1 and 2 respectively. Cylinder cam has four tracks, out of which the fourth track is kept idle. The A and B needles are moving in track 1 and 2 respectively and the C needle is moving in track 3. This is clearly shown in the needle set out diagram. The dial and cylinder needle will perform miss and knit stitch simultaneously during fabric production. That is yarn from feeder 1 forms miss stitch with dial needle and knit stitch with the cylinder needle. The yarn from feeder 2 produces knit stitch with dial needle and miss stitch with the cylinder needle. This has been repeated up to third course (6th feeder). In the fourth course, the yarn from feeder 7 produces miss stitch with dial and knit stitch with cylinder. The yarn from feeder 8 fed to the dial needle produces knit stitch. Third track 36th cylinder needle makes tuck stitch with the dial needle to produce bi-layer knitted fabric. This cycle has been repeated throughout the knitted fabric production. This is shown in the CAM set out diagram. Sample 1 is made of 20 Ne Cotton and 120 D Polypropylene, Sample 2 is made of 20 Ne Cotton and 240 D Polypropylene, Sample 3 is made of 40 Ne Cotton and 120 D Polypropylene and, Sample 4 is made of 40 Ne Cotton and 240 D Polypropylene.

Results and discussion

The results obtained from testing the bi layer knitted fabric samples which include geometrical and comfort properties.

Fabric dimensional parameters

Table 1 shows the wales per inch, course per inch, stitch density, loop length of polypropylene face and cotton face of various counts, thickness and GSM of polypropylene and cotton bi layer fabric of various combinations. In loop length, there is slight variation between Cotton and Polypropylene due to the machine settings. Stitch density calculated by the product of Wales per inch and course per inch for both cotton and polypropylene. Stitch density varies from coarser to medium for both cotton and polypropylene. GSM of the fabric varies according to the count of cotton and denier of polypropylene in different combinations.

Fabric shrinkage

Shrinkage behaviour of samples was determined after washing. It was inferred that there was no shrinkage on both faces of the fabric.

Comfort properties

Results of various comfort properties such as air permeability, water vapour permeability, wetting, wicking, absorbency, drying behaviour and thermal insulation of the bi-layer knitted fabric samples were presented in Table 2.

Air permeability

Air permeability test was carried out under two conditions: Drystate and Wet state.

Air permeability in dry state

Table 2 shows the average test results of air permeability performed on samples 1 – 4, both dry and wet state. Sample 3 shows the highest air permeability in dry state followed by sample 1, 4 and 2. This was based on air flow principle which states that the flow of air will be less in coarser count and more in finer count due to lower thickness of sample 3. Figure 1 shows the graphical representation of air permeability of samples (1-4).

Air permeability in wet state

During action, usually sportsmen’s garment will be of sweat. In this wet state, fabric should have enough air permeability so that vapour transfer will be good. If air permeability in wet state is not good, it would lead to accumulation of sweat on the skin and thus cause hypothermia. Thus, this property is very important.

Figure 2 shows that Sample 3 has more air permeability in wet state followed by sample 1, 4 and 2. In wet state cotton absorbs moisture and swells which decreases the air pores, and any water present in free liquid state (i.e. unabsorbed state) between the yarns also hampers the air movement across the fabric. Thus, the air permeability of wet state fabric was comparatively lower than the dry state fabric.

In both wet and dry state, air permeability values of all the all samples more or less same on both sides of bi-layer fabric. Cotton yarn count has major influence on air permeability of double layer knitted fabric than polypropylene yarn count.

Moisture vapour transfer

In steady state, moisture vapour transport through fabrics is controlled by a diffusion process that is influenced by fabric structure, fabric thickness and openness. Fibre-related factors, such as cross sectional shape and moisture absorbing properties, do not play a significant role. The fabric having low moisture vapour permeability is unable to pass sufficient perspiration and this leads to sweat accumulation in the clothing and hence discomfort.

The average of test results of moisture vapour transfer performed on selected combinations of bi layer fabric shown in Table 2. Maximum moisture vapour permeability is seen (Figure 3) in sample 3 followed by sample 1, 4 and sample 2.

Wetting (sinking method)

The evaluation of contact angle between a liquid and solid surface indicates wettability, changes in the level of surface energy, and changes in the chemical and super molecular structure of the surfaces.

The wetting test were carried out with five trials for each combination and table 2 shows the average of test results of wetting performed on selected combinations of bi layer fabric. The results are shown in Figure 4. Sample 3 has shown lower wetting time followed by sample 4, sample 1 and sample 2. This is due to the changes in surface properties of the fibres, size and number of pores in the fabric structure.

Wicking

Wicking is the spontaneous flow of a liquid in a porous substrate, driven by capillary forces. The capillary forces are caused by wetting is wicking. Wicking property of a fabric mainly depends on characteristics of fibre and structure of component yarns and the fabric. Average longitudinal and transverse wicking rate for each sample were shown in Table 2.

Longitudinal wicking

Wicking height determines the liquid transporting ability of a fabric. Faster the rate of wicking better will be the sweat transporting ability and more comfortable will the fabric be. This is because as soon as a drop of sweat will form on the skin, the fabric will transfer it through capillary action and excess sweat would not be left standing on the skin. Longitudinal wicking was observed only in Polypropylene side since it is well known that the wicking of cotton is very low as compared to polypropylene. Figure 5 shows that 240D Polypropylene having higher wicking rate as compared to 120D Polypropylene.

A wicking height of 11 cm and 10.7 cm was observed in five minutes in Wales and course directions respectively. This difference is due to the fact that more capillaries are present in wale direction, so that water can easily rise in wale direction. The saturation level of 14.3 cm and 12.3 cm in wales and course direction was attained with further increase in time of 10 mins. (Note: wicking height of cotton was negligible = 0.7 cm in 5 mins).

Transverse wicking

Analysis of transverse wicking characteristics of the fabric is more important than longitudinal wicking because the perspiration (sweat) transfer from skin involves its movement through the lateral direction of the fabric.

Polypropylene (240D) shows (Figure 6) little higher wicking rate as compared to finer Polypropylene (120D). This may be due to pore size, number of pores and their distribution in the fabric structure. (NOTE: Transverse wicking rate of cotton is negligible (0.0087 mm²/s).

Absorbency

When fabric is subjected to heavy sweating conditions, not all the absorbed sweat by the fabric absorbs can be given off to the atmosphere instantaneously. So to prevent the wearer from feeling wet and clammy the moisture should be stored in the fabric. More the amount of moisture that can be stored by the fabric better would be the performance of the fabric under moderate to heavy sweating conditions.

Maximum absorbency was found (Figure 7) in sample 3 followed by sample 1, sample 4 and sample 2. From the results shown in table 2 the bi-layer samples having high amount of water absorbency (Absorbency& 200 per cent of fabric weight) when compared to single layer structure. Presence of cotton in sample has major influence on absorbency because cotton has much more affinity for water and is highly hydrophilic with regain of 8 per cent, Polypropylene on other hand has a regain of only ~0.1 per cent. So the cotton fabric absorbs water more easily.

Drying behaviour

Moisture transfer is a critical factor for Thermoregulation of the body heat. Moisture on the skin or clothing increases the heat loss of the body and also affects the overall performance and endurance of the body. So, the clothing should have absorbing and also quick dry abilities.

It can be seen from the Figure 8 that finer sample 3 has the higher amount water loss followed by sample 1, sample 4 and sample 2. Polypropylene has higher drying rate compared to cotton because it doesn’t have any chemical interaction with water instead it repels water due to its hydrophobic chains. Cotton forms hydrogen bond with water and so once absorbed water gets released slowly compared to polypropylene.

Thermal insulation

The fabric insulation consists of insulation provided by the yarn and the air trapped in the loop structure. Thermal resistance is a function of fabric material, thickness and fabric structure. Heat from the body is expelled by two mechanisms-wet heat and dry heat transfer. Wet heat transfer is the heat transfer through the mechanism of sweat evaporation. So it is quantified by air and water vapour permeability. The dry heat transfer is the heat transfer under no or very little sweating.

Thermal insulation values are shown in Figure 9. Sample 2 shows better insulation due to its higher thickness and more air being trapped in the loop structure followed by sample 1, sample 4 and sample 3. Figure 9 shows the graphical representation of thermal insulation of samples (1-4).

Statistical analysis

The T-test was carried out to find the difference among the samples in terms of air permeability, moisture vapour transfer, wetting, longitudinal wicking, transverse wicking, absorbency, drying, and thermal insulation. Results of T-test are given in Table 3.

In terms of air permeability in dry state and moisture vapour transfer all fabthem. In wet state, almost all the samples had significant difference except samples S1&S2 and S2&S1. Remaining all other properties (wetting, longitudinal wicking, transverse wicking, absorbency, drying, and thermal insulation) of all samples had insignificant difference among themselves.ric samples have significant difference among

Subjective study of developed sportswear

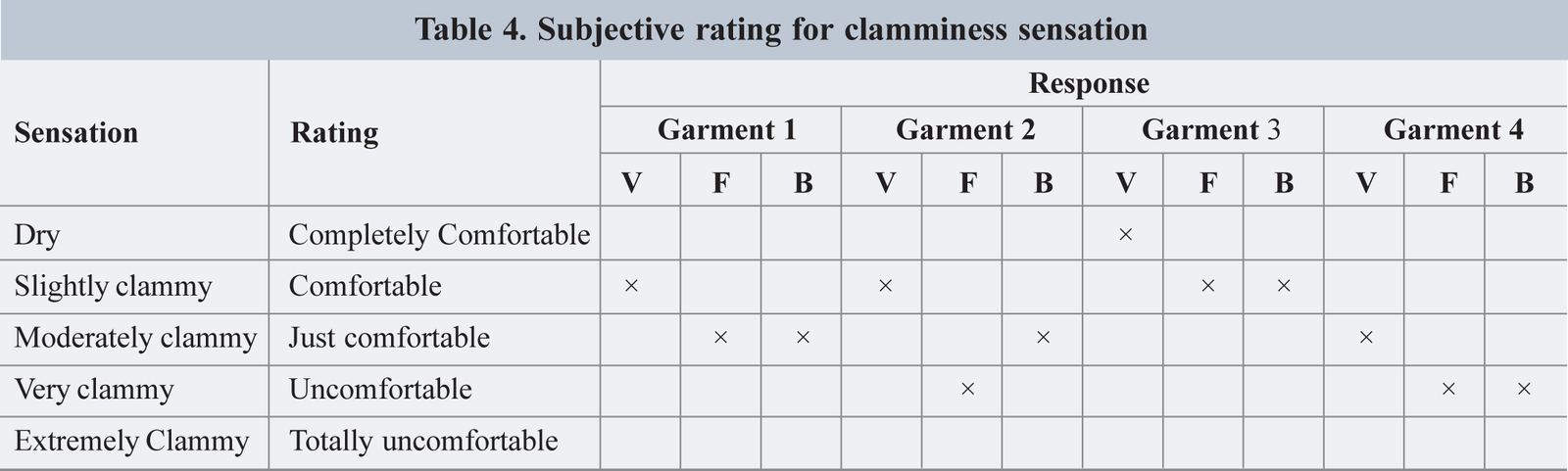

The sportswear was given to sports persons of volleyball, football, and basketball. Dampness, thermal and clammy sensations were studied and the ratings were given as shown in tables 4, 5 & 6. The study was conducted between the time interval 10-12 a.m.

• Garment 1: 20Ne/120D • Garment 2: 20Ne/240D

• Garment 3: 40Ne/120D • Garment 4: 40Ne/240D

Subject: Volleyball, football and basketball players

The results of the trail shows that the clamminess sensation was completely comfortable in garment 3 while playing volley ball and comfortable during foot ball and basket ball. Garment 2 and 4 were comfortable during volley ball and just comfortable & uncomfortable feeling during football and basketball. Garment 1 was comfortable during volleyball and just comfortable during football and basketball.

Dampness sensation was found to be just comfortable in garment 1 for all three games. Garment 2 and 4 shows just comfortable during volley ball and uncomfortable during foot ball & basket ball. Garment 3 was comfortable during volleyball and just comfortable during football and basketball.

Thermal sensation was found to be comfortable during volleyball and just comfortable during football and basket ball in garment 3. Garment 2 and 4 were just comfortable during volley ball and uncomfortable during football and basketball. Garment 1 was just comfortable in all three games.

Conclusion

From the studies conducted to assess the performance of bilayer knitted fabrics it is concluded that significantly higher air permeability in both the layers of 40Ne/120 D fabric, quick wicking in polypropylene layer, more waster absorbency in cotton layer was found in sample 40Ne/120D, Moisture vapour rate more or less same on both sides of bi-layer fabric 40Ne/120D sample transfers the high rate of moisture vapour, the sample 20Ne/240D has higher thermal insulation, Dryness of bi-layer fabric shows that the amount of water loss found higher in sample 40Ne/120 D while comparing other combinations. Hence, the bi-layer knitted fabric structure can be used as active sportswear clothing for sports such as volleyball, basketball and football