Germany based Christoph Liebers, a leading producer of elements for knitting machines, has introduced its latest development, new nano sinkers, at the ITMA trade fair for textile machinery that took place in Milan last November. Under the slogan Sinkers are silver, but nano is golden!, the company presented a new generation of knitting elements in gold, with innovative structured surfaces, designed to increase durability of the knitting components and reduce friction during production.

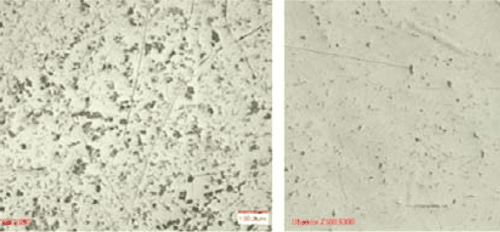

“Those who want to understand the advantages of these nanos needs to look at the pieces of gold under the microscope,” said Michael Starke, one of the Managing Directors and also the sonin- law of the founder of Christoph Liebers. The surface, which is no longer flawlessly smooth, is characterised by a host of tiny inclusions, a fraction of a millimetre long. In these microscopic cavities, oil is held for the better lubrication of knitting machines.,/p>

These irregularities, undetectable to the untrained eye but nevertheless intentional, just like small cells, keep the lubrication film even. Each and every lubrication film, which protects the sinkers, splits at a certain temperature, according to Christoph Liebers. “Because of a lack of oil on large parts of sinker surfaces, there is significantly more friction than with the new nanos,” Starke added. “In contrast, the lower wear by using nanos has a whole range of advantages besides lower temperatures.”

Achieving less friction

One of the main advantages of the new surface is the reduction of friction, which is linked to reduced wear and lower temperatures. Energy consumption is also said to be lowered by less friction, which results in a longer life of new sinkers, according to the manufacturer. Another advantage is that lower friction is said to produce less abrasion, which normally pollutes the machines and the knitwear they are producing. The company had a statistical series of certifying tests carried out by the Fraunhofer institute for Layer and Surface Technology in Braunschweig.

In the test assembly, a test body, whose surface corresponds to that of the sinker, was moved back and forth on a similar test body made from steel, with a vertical force and a frequency that is common in production. On the traditional sinker, the oil film split after around five minutes, the friction value showing afterwards a constant increasing trend.

Under the microscope, the significant differences become clearly visible. On the left side the structured surface of the “nanos.” Contrary to this, the right side shows the surface of the standard sinkers with their mirror-like sleekness. The tests were carried out by the “Fraunhofer Institut für Schicht- und Oberflächentechnik” in Braunschweig. The result was different for the nanos. Because of the pieces of gold, the oil film was kept constant even after the one-and-a-half-hour test time. According to the test findings, the surfaces of the nanos “reveal significant differences in friction value and in the danger of wear.”

Specialist in knitting elements

Christoph Liebers is a medium-sized company based in Southern Germany which was newly founded in 1975 by Christoph Liebers. The family tradition in sinkers production dates back to 1876, when Ernst Liebers founded the first factory for spare parts of knitting machines in Chemnitz. Later, in 1912, the first contacts were established with remote countries – even deliveries to Egypt and to the Arab world began – and business relationships with knitting centres of the industrialised parts of the world were created.

In 1971 the company merged with its main competitor, and Christoph Liebers left the joint venture. The next year the tooling factory Chr. Liebers was established in Ingolstadt. And after a competitive prohibition of work, Christoph Liebers re-entered the development and production of sinkers.

In 1989 daughter Ulrike Starke (maiden name Liebers) and son Thomas Liebers join the company’s’ management. In 2000 Thomas Liebers and Michael Starke (son-in-law) were appointed Managing Directors.

Later, Sandra Liebers (daughter-in-law) completed the leading quartet. In 2007 and 2008 the company expanded by adding capacity for the production of sinkers and allowing future growth of the facility. Nowadays, the company supplies to more than 30,000 clients in over 90 countries. Despite its global focus, Christoph Liebers GmbH & Co. KG always remained a traditionally orientated family business.

Surfaces for sinkers and cylinder walls

With its new approach, the company has challenged the flawless silvery shine and a luxurious appearance of the sinkers’ surfaces that were being produced with a goal to achieve uncompromised smoothness. The ‘Ur-nanos’ glow a golden colour in the spotlight. Microscopic inclusions keep the oil film even while running and make the ‘nanos’ very energy efficient, reduce wear and lower the resulting temperature during production. For the knitters it also means less abrasion caused by metal-to-metal contact, reduced metal soil in the knitwear and a longer life for the knitting elements. The company’s new product, developed at the German sinkers production plant in Bavaria is seen by the company as a revolutionizing approach to the world of sinkers. For Michael Starke, opportunities for completely new cooperation models and partnerships have opened up. “We can easily imagine using the structured surface together with premium producers,” he commented.

The structured surface keeps the oil film more even in the machine during production. In the tests run by the Fraunhofer Institute, the coefficient of friction showed a constant decreasing trend even after a long period of time, whereas the coefficient of friction of the standard surface started increasing after a few minutes.

If both sides capitalize on the surfaces of the nanos, according to Managing Director Starke’s calculations, then the advantages in its use will be stronger. That could mean even less wear, energy consumption, and abrasion, and even lower temperatures. It my also mean an even longer life for the knitting elements and careful use in the knitting machines, the company reports.

The experts at the German Fraunhofer Institute for Layer and Surface Technology in Braunschweig came to the conclusion that between the standard sinkers and the new ‘nanos’ from Christoph Liebers GmbH & Co. KG “significant differences were visible in the coefficient of friction and in the amount of wear.”

“If knitting machine manufacturers want to reap the benefits of the nano development, then in the future they’ll turn their path towards Gaimersheim,” the company reports. The market lies in close proximity to the Audi metropolis of Ingolstadt.