Comfort is a fundamental and universal need of a human being. Broadly there are four basic elements of clothing comfort, namely thermo-physiological aspect, sensorial or tactile aspect, physiological aspect and fitting comfort. The thermophysiological comfort concerns about the heat and moisture transmission characteristics through clothing, i.e. transmission of heat, air, and moisture (liquid and vapour). Different properties of the fabric have different effects on its comfort characteristics. For human, comfort is mandatory for entire body from chest to feet. Feet comfort mainly depends on foot wear and socks which prevent our feet from evaporating moisture. Sweat generation in feet depends on gender, age, activity level and environment.

Practicing and playing a high active sports place a lot of stress on the feet and makes things worse. Wet socks soften and weaken skin, making feet vulnerable to blisters. Our feet absorb more force during running than any other part of the body. Heat, moisture and friction work together to cause blisters. The trapped sweat quickly becomes smelly, because of bacteria that feed on it, producing the cheesy smell. Since going bare feet as much as possible is not a practical solution, it’s helpful to choose your socks and shoes wisely. Spinning on your own way means that you find to pick and choose the best ingredients.

There are different varieties of fibres, each suited to different applications. Also, socks don’t have to be 100 per cent of any fibre; that would be like eating a dish with no seasoning. Creating blend of fibres, each with their own special characteristics is a great way to devise an ideal socks. This paper reveals the unique characteristics of different fibres, blends used in commercial socks, moisture transfer through textiles and innovative fibre materials used in performance socks.

Sweat and Smell

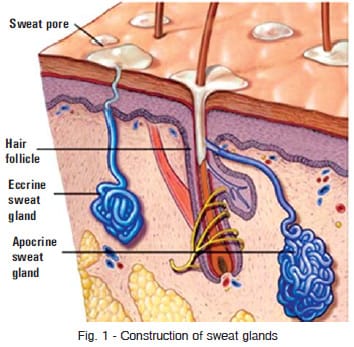

Human sweat glands

The temperature of skin plays an important role for any thermal sensation and a person feels comfortable within a narrow range of skin temperatures. The range of comfortable temperature for feet is 32 – 35°C. The number of working sweat glands varies between parts of the body – and also between different people. In a pair of feet there are normally about 250,000 sweat glands which typically produce about half a pint of perspiration a day. Sweat glands are more concentrated on the feet than in any other part of the body. When sweating activity is low, only a small proportion of the glands will be working – as sweating increases, more glands are ‘recruited’.

The differences between people in terms of how much they sweat are in part due to how quickly and readily their glands are called into action. Sweat is mostly water. However, it does contain some salts, including sodium chloride – which is the reason for salty taste. There are two types of sweat glands in human body: Apocrine glands and eccrine glands (Fig.1). Eccrine sweat glands have a generalised distribution, with the highest density on the palms and soles. They are activated by emotional and thermal stimuli and are necessary forthermoregulation. The eccrine secretory unit consists of a coiled secretory portion that drains into a long thin duct whose apical portion called acrosyringium opens to the skin surface. Innervations of eccrine glands consist of postganglionic sympathetic fibres that have acetylcholine as the principal neurotransmitter. Apocrine glands are found near hair follicles especially scalp and armpits. They secrete sweat: A yellowish, thick fluid and happens in response to stresses. But there are no apocrine glands on your feet. Body odour is the by product of bacteria on your skin digesting the sweat produced by apocrine glands.

Reasons for smell

Sweat doesn’t smell bad when it’s produced. Some people including n average and lead to many problems liked problem which often accompanies sweaty feet is foot odour. The smell is caused by bacteria produced while wearing shoes. The bacteria are present because the feet produce sweat while we are wearing shoes and socks, and the moisture is retained to a certain degree. We rarely notice the amount of sweat produced by our feet because the socks do such a good job at collecting it throughout the day.

Staphy lococcus epidermidis and Bacillus subtilis are two types of bacteria that naturally live on the skin of your feet. They like living in the moist, warm environment your sock provides, but they also like life on a sweaty bare feet and they really like to eat an amino acid, leucine, found in the sweat from the eccrine glands in your feet. When these bacteria eat leucine they produce their own gassy by product: Isovaleric acid. This isovaleric acid is reason for both stinky cheese and stinky feet. Foot odour can be particularly pungent if you happen to be a person who has a lot of B subtilis living on your feet. Different bacteria produce different odours and if your feet tend to have a sulfuric or ammonia-like aroma, you can blame a different microorganism: Meet Brevibacterium linens.

B linens are the bacterium that gives the notoriously stinky Limburger cheese odour and it’s also the culprit behind most of the foot odour. B linens flourish in environments that are salty, and that are about 20 to 30 degrees Celsius. B linens like to eat the dry, dead skin cells on the soles of your feet -they don’t care if your soles are sweaty or not and as they digest your skin they produce rotten-egg odours (sulfur).

Effect of sweat in human health Practicing and playing a high active sports place a lot of stress on the feet and makes things worse. Wet socks soften and weaken skin, making feet vulnerable to blisters. Heat, moisture and friction work together to cause blisters. Foot blisters are the most common sports injury, frequently occurring on the toes, heel and ball of the foot. Research indicates those with foot blisters are 50 per cent more likely to experience an additional (more serious) training-related injury.

Socks

Requirements for good

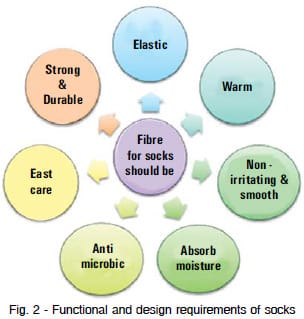

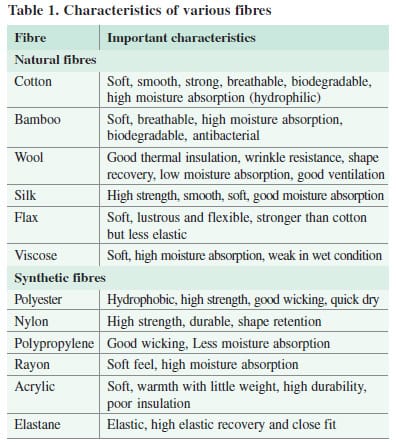

socks Socks provide relatively high friction to maintain traction for the foot inside the shoe. This is by design. But socks can be used in such a way as to lower friction. The socks should have the specific functional and design requirements (Figure 2). Socks are made from a blend of high-quality, super soft yarns at a state of the art manufacturing facility, should be comfortable and durable. The tensile strength of a fibre describes how much weight it can bear before it breaks and in these terms, silk is stronger than nylon which are both stronger than wool. There are lot of commercial sock yarns that mix merino (or wool) and nylon for this very reason. Nylon is stronger and helps to increase the wearability of a soft merino wool yarn. Wool fibre is inherently warm and elastic. The “crimp” of wool fibre is like a spring and holds the fibres apart gently, allowing air to be trapped in the spaces between the fibres which results in the insulating properties of wool. Soft and fine merino is often a popular choice for socks, but again is not as durable as other longer wools. Other non-irritating fibres like cotton or bamboo could be added to the mix as well to make the yarn more “cool” and slightly less insulating. The important characteristics of various natural and synthetic fibres are listed in table 1.

Fibre blends for performance of socks

Socks designed to be worn in shoes are going to have different characteristics than socks you might want to wear only at home and in bed. Not every pair of socks needs to be industrial strength, so there’s no way we can say there’s one and only one ideal sock fibre. Wearing the correct socks are crucialmany socks now having special properties that wick moisture away from your feet and prevent bacteria from growing. We specially engineered our socks to keep them very breathable for an optimal level of comfort and performance. We can look at the list of desired sock properties and find a combination of fibres that will work best for our requirement or activity. The blend of fibres used in commercial socks for various activities is listed in Table 2.

Moisture transmission through textiles

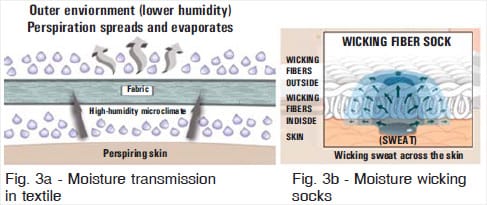

Moisture transmission through textiles (Figure 3a) has a great influence on the thermo-physiological comfort of the human body which is carried out through perspiration both in vapour and liquid form. The clothing to be worn should allow this perspiration to be transferred to the atmosphere in order to maintain the thermal balance of the body.

The processes which play the major role in moisture transmission in a particular situation are dependent on the moisture content of the fabric, the type of material used, the perspiration rate and the atmospheric conditions, such as humidity, temperature and wind speed. At higher activity levels and/or at higher atmospheric temperatures, the production of heat is very high, which activates the sweat glands to produce liquid perspiration as well. During sweating, if the clothing moisture transfer rate is slow, the relative and absolute humidity levels of the clothing microclimate will increase suppressing the evaporation of sweat. The transmission of moisture through textile materials in liquid form is mainly due to the fibre–water molecular attraction at the surface of the fibre materials, which is mainly determined by the surface tension and the effective capillary pore distribution. Clo value for socks is 0.01 and socks with knee length is 0.1 (1 Clo – amount of clothing required by a resting human to be comfortable at a room temp of 21 °C).

Moisture wicking socks

High skin moisture causes high skin friction and more likelihood of blisters. The initial goal of a sock is to absorb moisture (perspiration) to keep the skin dry (Figure 3b). But because of the sheer volume of moisture encountered, absorption alone won’t always be adequate- the absorptive capacity of any sock can be exceeded. Some socks move moisture away from the skin – from the skin side of sock to the shoe side of sock in a process known as wicking. This wicking function is achieved by socks manufacturers by using fibres in a way that sets up a moisture gradient to facilitate moisture movement in this direction. Socks have many functions and fibres are selected for their construction accordingly. Thermal insulation, cushioning, durability, quick drying and ability to maintain shape these will demand certain fibre properties. Wicking fibre socks all claim to keep feet dry but there is a challenge put forth for quick drying. Most wicking fibres are made from polyester, acrylic, nylon or wool and are Hydrophilic (water liking) because they have positive & negative charges on their surfaces. This attracts the negative & positive charges of the water or sweat molecules. Hence, there is a demand raise for innovative fibres which absorbs more moisture and release the moisture to outer and become quick dry. Many new fibres are innovated and available in the market but few of them are dealt in this area.

New fibres used in socks

Merino wool

Merino wool comes from the Merino breed of sheep, a type of sheep that has been prized for its high quality wool for generations. Merino wool can be made into all types of garments as the benefits of this type of wool are numerous, but it is particularly wonderful in a sturdy pair of socks. Merino wool socks perform for your feet as like same job the wool performed. The wool is able to help your feet to regulate their own body temperature, keep them dry, resist odours, and be naturally soft (Figure 4a). Merino wool so you have a pair of socks that are warm when you need them to be, cool when you need them to be, and naturally wick away moisture to allow you to prevent athlete’s feet, blistering, and discomfort.

Drymax

Moisture transmission through textile is wetting followed by wicking. Wetting is a prerequisite for wicking. Wicking fibres contains positive and negative charges on their surface and attracts positive and negative charges of water. Once wicking fibres get wet, they stay wet and so do you, until long after you stop sweating. According to the laws of physics, no single fibre technology can attract and repel moisture at the same time. To overcome this, Drymax products utilize two opposite type fibre technologies interwoven to form inner and outer layers.

Super Hydrophobic Fibre Technology Drymax fibres do not wick because they are Super Hydrophobic (moisture repelling). At the molecular level, moisture doesn’t adhere to the inner layer of Drymax terry loops (Fig.4b). When sweat droplets move through the Drymax fibres they stay together and move instantly through the fibers. Drymax stays dry and therefore needs no drying time to keep the skin dry. Drymax fibres do not carry surface charges, so the negative & positive charges of water are not attracted to Drymax fibres. Notice the water exits the Drymax Fibre socks as whole droplets. Drymax products are stiffer, good shape retention and can be easily blended with polyester and nylon for abrasion and reinforcement.

Coolmax

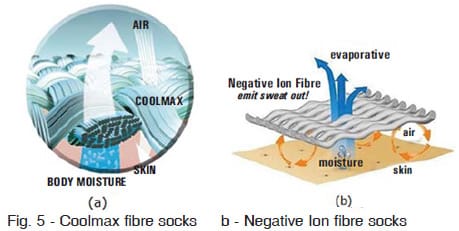

Coolmax socks developed by Invista, effectively move perspiration away from the surface of the skin. The thermoregulatory effect of moisture transport helps keep low skin temperature, allowing the wearer to feel cooler and more comfortable. Modified cross sections of the Coolmax sock fibre create a large surface area versus circular fibre. Larger the surface area, faster the rate of evaporation and evaporation causes cooling. Coolmax fibre technology actively draws moisture away from the skin surface, dispersing it and evaporates rapidly, thus keeping you feeling cool and dry. The moisture management performance of Coolmax socks is inherent to the fibre structure itself (Figure 5a); therefore, the performance cannot be washed off. The best fit and shape is achieved through blending of Coolmax with Lycra.

Negative Ion fibre

Negative ion fibre adopted to reach the best moisture wicking and odour resistant effects. Negative ions clear the air of dust, mould spores, pollen, pet dander, odours, cigarette smoke, bacteria and viruses. Negative ion fibre inside socks (Figure 5b) can effectively emit the sweat of feet to outside natural cotton. These socks are made of 65 per cent Combed Cotton, 23 per cent Negative Ion Sweat Emitting Fibre, 12 per cent Spandex. The combed cotton absorbs the sweat more and then evaporates, can feel more comfortable in wearing. This is appropriate for ladies and men daily wearing.

Conclusion

Moisture wicking and transmission behaviour of socks enhances the performance and comfort level of wearer. Moisture wicking fibres like Coolmax, Dry max and others offer good wicking and excellent drying for various activities. The socks with modal fibre seems to be very less in the market and blending of modal with fibre like cotton, polyester, nylon, wool and tencel offers wide range of properties for hot and moist climate. Also, the right combination of new technical fibres, new knitting technologies and new production ideas, can create a range of

socks from simple to high tech applications