CHTC Fong’s has been committed to the development and manufacturing of dyeing and finishing equipment for more than 50 years. In the past decades, CHTC Fong’s devoted to the development of energy-saving and emission reduction machines and now it becomes the basic conditions for dyeing factories. Today, we live in a digital era, though in the traditional textile industry, CHTC Fong’s has been with the times. Together with its well-known brands: Fong’s, Monforts Fong’s, Xorella, THEN, Goller, FWT and Monforts, CHTC Fong’s dedicated in the development of Smart Dyeing & Finishing and join with the customers to build the intelligent dyeing factory.

The CHTC Fong’s Group will be presenting the “one-stop” sustainable solution in dyeing and finishing range of “pretreatment, dyeing, post-treatment and waste water treatment” at Shanghai Tex 2017 in Hall W5, A11 and yarn conditioning and heat setting in Hall E1, B70, Shanghai New International Expo Center, China from Nov 27th to Nov30th.

Fong’s Dyecowin High Temperature Dyeing Machine

Application: Most knitted and woven synthetic fabrics in polyester, nylon and their blends with or without spandex.

Dyecowin is the revolutionary high temperature dyeing machine setting new standards for the industry. It is integrated with the cutting-edge patented technologies to cut down the liquor ratio and to enhance the productivity of the dyeing processes.

Reduce Production Cost: Dyecowin is a major breakthrough in the long tube machine operating with a much lower running liquor ratio as low as 1:5. The patented fluid distributor at the rear of the machine can effectively adjust the distribution of dyeing liquor according to different fabric types, ensuring an organised fabric stacking pattern.

Optimize the Dyeing Quality: The winchless design can overcome the tangling problem on the conventional dyeing machines. The fabric surface defects such as scratch marks and light spots caused by unsynchronized motion between nozzle and winch can so be avoided. The patented “CONJET” nozzle technology can ensure high quality of finished products by enabling automatic and precise adjustments of flow volume and nozzle pressure.

Enhance Productivity and Efficiency: The rectangular fabric transportation pipe allows fabric to have free relaxation and run smoothly along the channel, thus reducing crease marks effectively. This design also favours open width dyeing so as to simplify the production process. The patented stainless steel storage chamber is capable of increasing the loading capacity, combining with the use of “CONJET” nozzle, sensitive fabric can be run smoothly without scratching and snapping. The surface quality of fabric is assured with minimised cycle time.

FC30EX Program Controller: Its latest generation program controller – FC30EX can integrate with its Viewtex and THENTDS central computer system, providing a comprehensive control management.

Then Airflow Airjetwin Aerodynamic High Temperature Dyeing Machine

CHTC Fong’s has always been listening to customer and striving to satisfy the market needs. AIRJETWIN high temperature airflow dyeing machine, its latest generation of dyeing equipment, is now being offered to fulfill the various requirements of dying process nowadays. Through finite element analysis FEA), the airflow and water flow situation is well-analysed for design optimisation. In addition, by combining different THEN’S and Fong’s product advantages, the entire performance is further enhanced through a holistic design integration.

Single-Blower for Multi-Tube Design: By utilising single blower with frequency inverter and optimising pipe network design, the air volumetric flow rate of each tube is evenly distributed.

Integrating Nozzle System: By adjusting various combinations of multiple spraying nozzle and sprayers, the best dyeing performance of a huge variety of fabrics can be achieved.

XY Internal Plaiter: Fabric is capable of being two-way (horizontal and vertical) plaited inside the vessel to organise the fabric stacking pattern inside the storage chamber. It allows the smooth fabric lifting, enhancing the fabric lifting speed and reducing fabric tangling in the chamber.

Overhead Sprinkler System: Effective cleaning is provided through purging to rinse the kier head, ensure no residue colour is left.

Goller Sintensa Cyclone Tandem High Efficiency Washing Compartment

The newly-designed GOLLER washing compartment – Sintensa Cyclone Tandem reduces fabric’s running tension by means of the following two points. By optimising fabric’s running route. The optimised fabric’s running route and the increased cladding intensity of the driven rollers and driven drum scan keep the speed of the running fabric in accord with the speed of driven rollers and driven drums, stabilise the processing conditions for fabric in the washing compartment and enhance the accuracy of synchronization so as to facilitate the minimisation the running tension of fabric.

By the specially-designed rotor being installed on the driven drum (perforated). The rationale behind is that when the range is running, the rotor can rotates at different speeds under liquor and the high-speed water stirring of rotor can result in low pressure and thus achieving the suction effect of the running fabric. As a result of this, the problem of fabric-slipping can be avoided and the lower running tension can be resulted.

The new generation of GOLLER high efficiency washing compartment – Sintensa Cyclone Tandem is an innovation to the typical washing compartment in large size and in large volume, which can indeed guarantee energy-saving, emission reduction and production costs-saving and make the open-width washing process for knitted fabric more smooth and efficient.

Goller Effecta Modul Anti-Curl High Performance Washing Compartment

Goller Effecta Modul Anti-Curl is a newly-designed washing compartment which maximises the flexibility in applications and brings the washing experiences to a brand new level.

By minimizing the occurrence of curling edge and crease marks Effecta Modul Anti-Curl is designed particularly for Woven bottom weight and denim with high content of elastic weft processing. The ingenious way of putting the 2 rows of middle support rollers between the row of top rollers and the row of bottom rollers of Effecta Modul Anti-Curl has substantially shortened the free fabric path in between and thus minimising the occurrence of curling edge and crease marks. A higher washing efficiency can also be achieved since the extra 2 rows of middle support rollers provide more nips for fabrics during washing process.

By enhancing the compatibility of EFFECTA with different units EFFECTA Modul Anti-Curl is designed specifically for enhancing the compatibility of EFFECTA with different units. It applies the same design principle as the one of SINTENSA Cyclone Tandemby incorporating the modular-design intermediated trough with squeezer into the washing compartment – EFFECTA Modul Anti-Curlin this case. This modular design has further enhanced the compatibility of EFFECTA with the latest version of Sintensa washing compartment- SINTENSA Cyclone Tandem, Oxidator chemical application, swelling, shrinkage and washing compartment and Univers a dwelling and washing compartment, etc. With the advancement of applications compatibility, EFFECTA Modul Anti-Curl not only complete Goller’s product portfolio but also enable Goller to be excelled in every continuous open-width washing occasion.

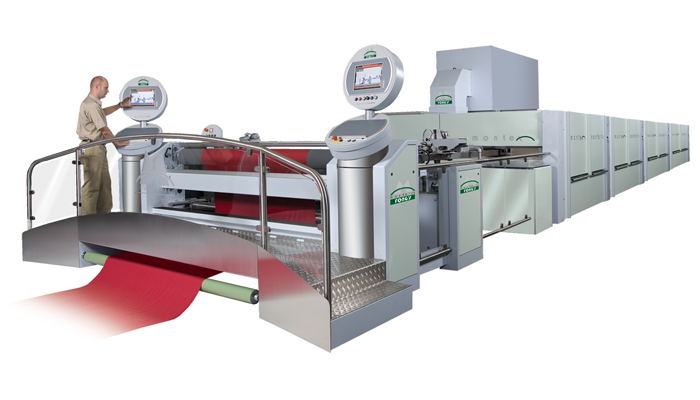

Monforts Fong’s Montex 6500 Air Filtration Omni Stenter Frame

Montex 6500 Air Filtration Omni (Abbreviation 6500 Omni), is based on the Montex 6500 stenter range in combination of the most advanced heat recovery and air filtration technology to evolve this stenter range into a more advanced environmental friendly machine.

The heat recovery and air filtration device of this 6500 Omni stenter can filter the wax and oil from the exhausted air with high efficient but low energy consumption. The heat recovery is so high which could contribute the textile industry to achieve low carbon release target a step further.

The modular design could allow different space requirement by different textile mills. Also this device runs with automatic cleaning function controlled by PLC by running its nozzles along the bar over the top of the filtration units. This will minimise the daily maintenance to the machine.

TwinAir: Monforts patented Twin-Air technology allows top and bottom airflow to be regulated separately. When drying without marking and the most even temperature possible across the fabric. Also, it also could be equipped with Optiscan for Auto-Balance system.

For this standard Nozzle System CAD Stream, its “Lay-on-Air” fabric supporting properties in air and with bulking effect through increased volume by its microtumbler effect. Attractive cost/ benefit ration with higher evaporation rates. It also provides continuous fabric support even at the chamber transition points.

- CAD stream E, suitable to be used with nominal width 260 cm or above, the nozzle width could be adjusted to nominal width to 180 cm to adapt to narrow fabric width

- CAD stream Slot, combined round and slot nozzles, new slot nozzle design for high-pile and terry cloth fabrics. Also suitable for dyeing processes on the stenter

- Qualitex 750 Programmable logic process controller (PLC). Expandable and adaptable for practically all tasks arising in modern textile finishing. It has Programmable control functions, Operation of the range via panels along the machine, Storage of set-up data sets, Integration of setting values for measuring and control devices, Batch management, Network interfacing, Automatic nozzle pressure control, Prepared for teleservice, Maintenance and two-loop system via touch panels This system also run with its developed Monformatic which is control system for technology in combination of treatment processes (drying and heat-setting) to achieve exact maintenance of the dwell time. When the heat-setting point is reached, the fan speed is automatically adjusted. A further contribution to greater cost-effectiveness.

Its function including measurement of the heat absorption of each fabric from the circulation air, determination of exact heatsetting times even with varying parameters such as deviating initial moisture content or reduced circulating air due to clogged filters or fan failure. Besides, the exact determination of the heatsetting point is the reliable basis for optimum speed control and thus for cost-effective machine utilisation and optimum exhaust air conditions at all times. The payback is energy consumption being under control which always knows the right heat-setting point. This could eliminate the need for allowances and avoid the risk of insufficient heat-setting.

Besides, the system could run with self-developed central processing control software “Q-soft”. This software is for production planning and documentation with a central interface. All process data can be stored in a standardized database (ODBC=Open Data Base Connectivity) where all set points and actual values are filed with read and write access for set points. Three levels of networking interfacing are possible: 1) Interfacing to your network, 2) Output to a PC with graphic presentation (Monforlogic), 3) Interfacing with a process control system to include machines from other manufacturers as well.