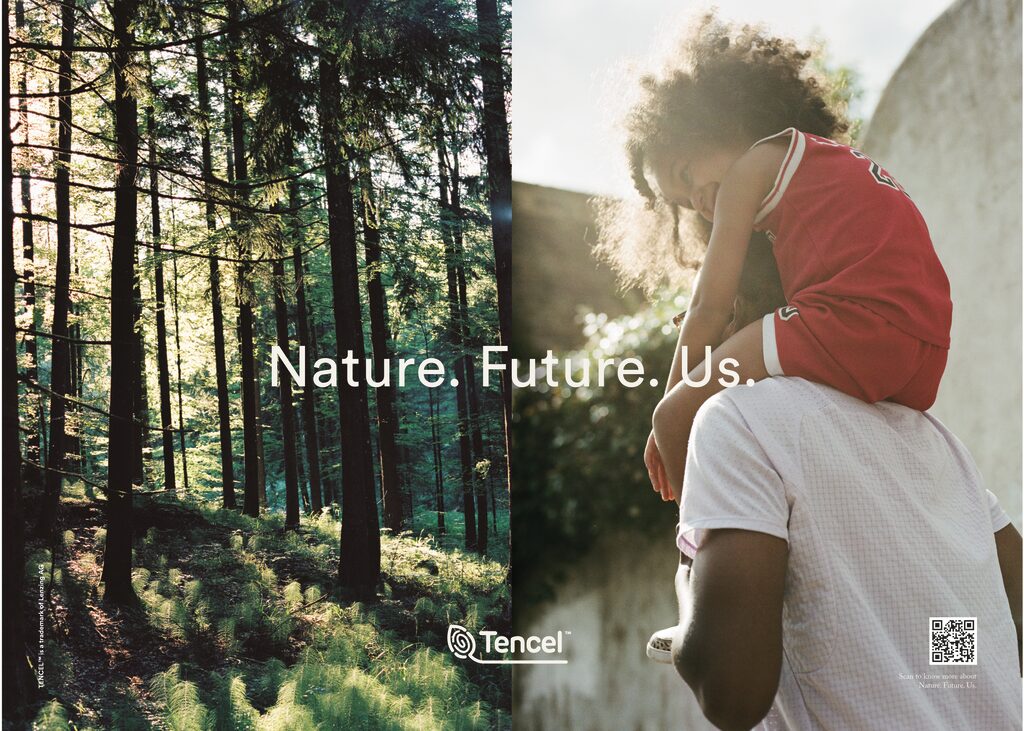

The Lenzing Group, a leading supplier of regenerated cellulose fibers for the textile and nonwovens industries, unveiled the latest evolution of its flagship textile brand TENCEL™, with a refreshed branding theme of “Nature. Future. Us.”. The updated brand identity embodies TENCEL™’s ethos of striving to embrace innovation and empower collaboration, with a focus on being a catalyst of change in the textile industry to safeguard the planet’s shared future1. The evolution of TENCEL™ stems from the brand’s deep respect for the planet1,3 that has been increasingly endorsed by consumers and value chain partners. The strategic repositioning will enable TENCEL™ to navigate the evolving landscape of the textile industry1,2 through the continuous commitment to delivering eco-conscious3 and resource-efficient4 fiber solutions.

The Lenzing Group, a leading supplier of regenerated cellulose fibers for the textile and nonwovens industries, unveiled the latest evolution of its flagship textile brand TENCEL™, with a refreshed branding theme of “Nature. Future. Us.”. The updated brand identity embodies TENCEL™’s ethos of striving to embrace innovation and empower collaboration, with a focus on being a catalyst of change in the textile industry to safeguard the planet’s shared future1. The evolution of TENCEL™ stems from the brand’s deep respect for the planet1,3 that has been increasingly endorsed by consumers and value chain partners. The strategic repositioning will enable TENCEL™ to navigate the evolving landscape of the textile industry1,2 through the continuous commitment to delivering eco-conscious3 and resource-efficient4 fiber solutions.

“The new theme ‘Nature. Future. Us.’ creates a very inspiring and inclusive voice for TENCEL™,” said Eva McGeorge, Senior Director of Global Marketing and Branding, Commercial Textiles, Lenzing AG. “Since introducing TENCEL™ Lyocell in 19925 and bolstering the overall brand positioning in 2018, TENCEL™ has been striving to bring innovative, sustainable textile fibers to the world1,2,3. The latest TENCEL™ brand evolution expands on our vision to spearhead resource-efficient4 and circular business practices1,6,7 attributed to our fibers, from raw material sourcing8 to end-of-life disposal of consumer products9. To facilitate real change in the value chain, everyone in the industry needs to transform together1,2. We will continue to build stronger collaborations and dedicate our efforts to creating a future for fashion that we can all be proud of.1,2”

Harnessing the power of innovation, collaboration and transparency

TENCEL™ is a brand founded on deep-seated respect for nature1,4. TENCEL™ branded regenerated10, biodegradable9 fibers are carefully sourced from sustainably managed forests8 and produced using resource-efficient methods4. To enhance circularity, Lenzing has been experimenting with and using waste materials like orange peel and cotton waste in the production of limited edition TENCEL™ Lyocell fibers, showcasing the brand’s unwavering commitment to championing sustainable textile innovation1. The growth of the TENCEL™ brand has also been fueled by collaboration. From the first waterless dyeing technology11 for wood-based cellulosic fibers to the first plastic-free alternative12 for stretch fabrics, TENCEL™ has been a catalyst in the revolution of fiber processing and applications. Collaboration has also brought the products made using fiber innovations to fashion shows, red carpets and retailers, extending TENCEL™’s reach.

In an industry where transparency is highly valued, TENCEL™ published its full set of fiber claims on a dedicated webpage, offering unprecedented visibility2 of raw material certification in the industry. Lenzing’s fiber identification technology enables the traceability of TENCEL™ fibers across all stages of textile production. This not only helps strengthen trust within the value chain, but also empowers consumers to make informed purchasing decisions.

“When consumers see the TENCEL™ trademark, they can rest assured that they are choosing renewable, traceable fibers13 that guarantee quality14 and comfort15. As we foster fiber innovation, we will continue to bolster trust and collaboration with like-minded partners, to empower value chain customers and amplify our impact1,2. We will also further refine our fiber identification technologies and Lenzing E-Branding Service offerings, to make transparency and traceability a norm across various stages of textile production,” said Kit Ping Au-Yeung, Executive Vice President of Global Textiles Business at Lenzing AG. The new TENCEL™ branding will be unveiled during the Intertextile Shanghai Apparel Fabrics Trade Fair, on August 27–29, 2024, at the Lenzing booth E55 at Hall 4.1.

1 With a process in place that factors in rapidly evolving regulatory requirements when developing and updating claims, TENCEL™ provides QR-coded claims and a Claims webpage that offers value chain partners and conscious consumers more clarity on what its fibers offer.

2 TENCEL™ Lyocell and Modal fibers are certified with the EU Ecolabel for textile products (license no. AT/016/001) for environmental excellence.

3 TENCEL™ Lyocell and Modal fibers are made with at least 50% less carbon emissions and water consumption, compared to generic (unbranded) lyocell and modal. The results were calculated according to LCA standards (ISO 14040/44) and are made available via the Higg Materials Sustainability Index (MSI) v3.7 by Cascale (formerly Sustainable Apparel Coalition).

4 TENCEL™ Lyocell fibers’ first production was in Alabama, U.S. in 1992 when the production facility was owned by Courtalds.

5 Lenzing – Focus Paper on Sustainability Strategy “Naturally Positive”, April 2024

6 TENCEL™ Lyocell fibers produced with REFIBRA™ technology use cotton textile waste as a raw material, in addition to wood. The fibers contain a minimum of 30% recycled material.

7 Adhering to the company’s commitment to environmental protection and resource preservation, Lenzing procure wood and pulp only from certified or controlled sustainable sources. In its Wood and Pulp Policy, Lenzing is committed to procuring wood and pulp exclusively from non-controversial sources.

8 LENZING™ Lyocell and Modal standard fibers are certified by TÜV AUSTRIA as biodegradable in soil, freshwater and marine environment.

9 TENCEL™ Lyocell and Modal fibers are made from wood, a natural and renewable raw material.

10 Lenzing partnered with technology start-up Exponent Envirotech to introduce ECOHUES™, a waterless dyeing technology to Lenzing’s cellulosic fibers. ECOHUES™ technology effectively replaces the use of water in the dyeing process with a non-aqueous solvent that is 99.8% reusable and streamlines the pre-treatment and finishing processes by nearly removing the need for soap washing after dyeing. This helps to reduce the overall water usage by 95% compared to traditional dyeing methods.

11 TENCEL™ Lyocell fibers are derived from the natural raw material wood and have been used to develop the industry’s first stretch fabrics that enable reduced usage of fossil-based materials.

12 TENCEL™ Lyocell and Modal fibers are produced with a molecular marker. This special identification technology ensures the authenticity and traceability of TENCEL™ fibers even after processing into textile products.

13 Both TENCEL™ Lyocell and Modal fibers have a high tenacity profile favoring processing stability. This enables TENCEL™ fibers to withstand faster production speeds in machinery, while at the same time making critical contributions to yarn strength and quality.

14 Lyocell and Modal fibers produced with Micro technology are the finest fibers within the TENCEL™ portfolio. This leads to increased softness and an even higher level of comfort.