Research teams from the Interdisciplinary Nanoscience Center at Aarhus University in Denmark have developed a method for separating elastane to enable recycling.

Research teams from the Interdisciplinary Nanoscience Center at Aarhus University in Denmark have developed a method for separating elastane to enable recycling.

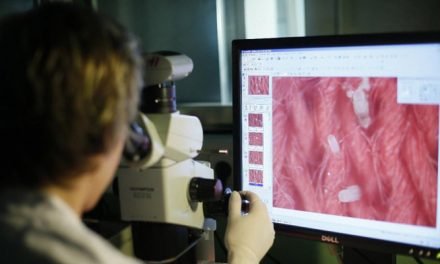

Issues around the separation of nylon and elastane yarns have being proving problematic for the textile recycling industry for many years. In products such as sportswear and women’s hosiery, for example, nylon fibre is often wrapped around an elastane core during the yarn preparation stage, and as such is virtually impossible to separate back into the respective fibres for recycling.

Writing in a new paper, ‘Selective chemical disassembly of elastane fibres and polyurethane coatings in textiles’, assistant professor Steffan Kvist Kristensen, part of the research team at Aarhus noted that the key to the process was breaking down the many links in the elastane chain which consist of long chains of molecules.

“We’ve developed a method to remove elastane completely from nylon,” he said. “We’re not quite there yet with cotton, because some of the cotton fibres are broken down in the process. But we believe that, with some minor adjustments, we can solve this problem. In other words, we can disassemble the fabric so that we can recycle far more textiles in the future.”

With similar research also taking place recently at the Vienna University of Technology (TU Wien) in Austria, the team found that the fibres in nylon stockings would only break apart if the long chains of molecules were broken.

“The many links in the elastane chain are bound together by a small molecule called a diamine,” said Kristensen, adding that by heating the clothes to 225 degrees celsius and adding a specific alcohol, the team found a method to break down the bonds in elastane.

“When this happens, the chains fall apart and the materials separate. The whole process takes place in what is in effect a large pressure cooker that we feed the textiles into. We then add a little alcohol and some base and heat it up. Then we let it cook for just over four hours, and when we open the lid again, the different fibres will have been separated.”

Kristensen also noted that because most of the fibres in the clothes need to be recyclable, using harsh chemicals was not an option. Instead they used alcohol and added a potassium hydroxide base.

“Potassium hydroxide is one of the main ingredients in ordinary drain cleaner. We found that adding this accelerated the process. It simply increases the speed of the chemical reaction,” he said. “We’re pretty sure that potassium hydroxide increases the reactivity of our alcohol. Either that, or the bonds are broken down slightly by the potassium hydroxide, so it is easier for the alcohol to break them completely.”