Workflow automation is essential for standardized, economical production in textiles and garment manufacturing. At Texprocess Frankfurt, Zünd is presenting software tools for every phase of textile processing centered on Zünd high-performance digital cutting systems geared towards maximum efficiency.

Workflow automation is essential for standardized, economical production in textiles and garment manufacturing. At Texprocess Frankfurt, Zünd is presenting software tools for every phase of textile processing centered on Zünd high-performance digital cutting systems geared towards maximum efficiency.

There are many ways to optimize production and make it more efficient and profitable. Zünd, the Swiss digital cutting-system manufacturer, offers a variety of automation solutions designed specifically for digital textile cutting, many of which the company will be presenting at Booth C57 in Hall 8. These solutions help automate and standardize print and cut-file preparation and also support production monitoring and analysis, control the cutting process, and facilitate the removal of cut parts as well as logistics.

Intelligently automated production offers enormous opportunity for savings and helps eliminate potential sources of error. This is one of many insights attendees will gain from learning about Mind Cut Studio at Texprocess. Zünd’s modular workflow suite contains all essential functions for every phase of textile production and garment manufacturing. It can reliably detect patterns, compensate for material distortions, and nest parts for maximum material yield. In view of the rising cost of materials, maximum utilization is an essential component of a productive and profitable workflow. In addition, the software also offers flexible options for pattern matching, no matter whether the fabric is striped, checkered, or digitally printed. For efficient removal, cut parts must be quickly and clearly identifiable. Projected colour coding and parts information are a great way to help the operator identify and sort cut parts. With projection and monitor displays serving as visual aids, the parts removal process becomes easy, quick, and reliable.

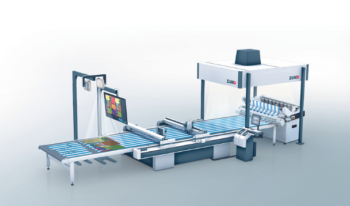

Zünd expertly combines digital cutting technology with state-of-the-art tooling and intelligent optical systems into complete, high-performance turnkey systems. The user retains maximum flexibility in terms of suitable cutting workflows, choice of materials, and short delivery times.

Zünd cutting systems are an integral part of a complete digital production workflow that allows garment and upholstery manufacturers to automate their production processes and simultaneously optimize the data flow. This results in significantly greater throughput, reduced error rates and production costs, which in turn enables much greater competitiveness. The audience in Frankfurt will be able to experience the Zünd dual-beam D3 cutter which offers industry-leading performance and productivity. Two independently operating beams can each accommodate up to three different tool modules and enable significant increases in throughput. The intelligent cutter-control system optimally distributes jobs across the two beams, thereby ensuring maximum productivity.