In general, the human body temperature is 37°C, the body temperature rises up during physical activity and body generates heat and as a result perspiration occurs. In twenty first century, clothing is an important issue for general consumer, active athletes and for those who practice sports just for fitness in their leisure time. The sports fabrics are generally ultra-breathable and have high heat and moisture management properties, light weight, fast drying properties and feature elasticity properties. The functional active sportswear requires light-weight, strecthability, air permeability, water vapour permeability, quick drying ability and sweat absorption.

In sports, player has to face so many problems such as feeling hot during run, improper stretch ability, give protection to body skin during fall on the ground and extra weight of the fabric. The moisture handling properties of sportswear during intense physical activity have been regarded as important factor in comfort aspects. The comfort perceptions of sportswear are influenced by wetting, drying ability and thermal related aspects. The increase of cloth weight due to sweat generated by the body, which makes wearer feel uncomfortable and affect the overall performance. Natural fibres such as modal and bamboo are hydrophilic in nature which evaporates moisture soon on the other hand polyester and micro denier polyester are hydrophobic, which has good moisture transportation and release. The objective of the research was to compare the properties of trilayer knitted structure made from different fibres. A fabric can be developed with moisture absorption and release properties, to achieve this layered knitted fabric have been developed with modal as outer layer or bamboo as outer layer, micro denier polyester as middle layer and polyester as inner layer. The aim of this research is to develop a garment suitable for sports person that can ensure easy body movement without stress on the part of the body. The developed garment can provide better thermal comfort throughout the game by preventing the body heat to rise in short time and evaporate sweat as sooner as possible so as to keep the body dry all the time.

Materials and methods

Samples were created using two different yarns with similar knitted structures.

Knitting machine

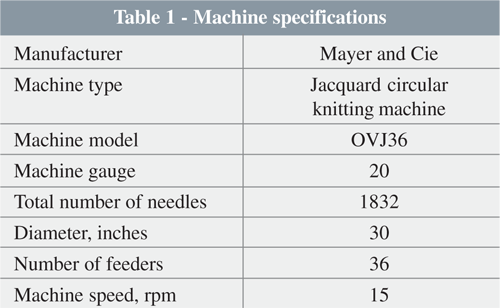

Fabrics were knitted using a Mayer and Cie OVJ136, double jersey jacquard circular knitting machine. The jacquard machine provided design flexibility and necessary capabilities for the research. The machine specifications are listed in Table 1.

Yarn

For the tri-layer knitted fabrics, two different yarns were chosen for outer layer due to their individual characteristics. The yarns varied in terms of fibre content and fibre type (Table 2).

Knitted structure

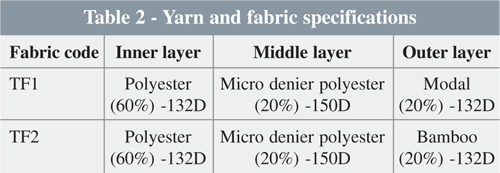

One of the ways of constructing a physiologically functional fabric is three-layer structure (Figure 1). The use of superfine or microfibre yarn enables production of dense fabrics leading to more effective capillary action, with better thermo-physiological regulation.

The tri-layer knitted fabrics were produced based on different yarn compositions. The dial needles knit at all odd feeders and cylinder needles knit at all even feeders. The cylinder needles knit at odd feeders in certain places as per the design. The diamond shape design with 36 course repeat is formed by twice the revolution of machine. The first half of design was produced by the first rotation of the machine and the second half of design which completes the diamond shape was produced by the second revolution of knitting machine. All cylinder needles knit modal/ bamboo yarn and all even needles knit polyester. The jacquard raising position is shown in Fig.2.

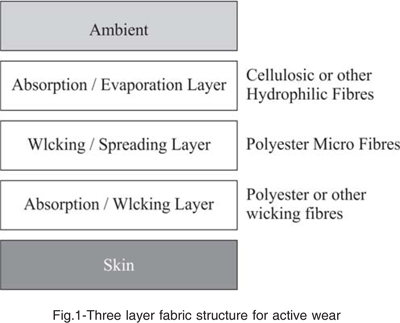

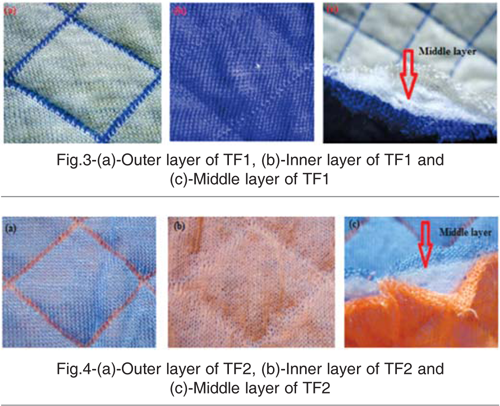

The two samples were produced as TF1: Modal as outer layer, micro denier polyester as middle layer and polyester as inner layer, TF2: Bamboo as outer layer, micro denier polyester as middle layer and polyester as inner layer.

Experimental

All fabric samples were habituated under standard atmospheric conditions of 21+1°C and 65 + 2 per cent RH for atleast 24 hours before testing. The air permeability is described as the rate of air flow passing perpendicularly through a known area, under a prescribed air pressure differentiated between the two surfaces of a material. Tests were performed according to standard ASTM MD737-96 using a air permeability tester. In longitudinal wicking, a strip of test fabric is suspended vertically with its lower edge immersed in reservoir of distilled water. The measured height of rise in a given time (10 minutes) was taken as a direct indication of the wickability of fabric. The transverse wicking was carried out using standard AATCC 198-2011. Static immersion method which follows the standard BS 3449 was used to evaluate the amount of water absorbed by the fabric. The drying behaviour of fabric was tested as a continuous process from absorption process. The fabrics got wet according to static immersion method were dried in drying oven at 30°C for 30 minutes to stimulate natural drying. The evaporative dish method according to standard BS 7109:1990 was used to determine water vapour permeability of fabrics. Thermal conductivity was determined using Lees disc method, is a property of materials that expresses the heat flux that will flow through the material if a certain temperature gradient exists over the material. The relationship between structures has been analysed using ANOVA with MS-excel 2007. Error bars with percentage has been computed using MS-excel 2007 software and shown in the figures (I).

Results and discussions

The geometrical properties are shown in below table 3:

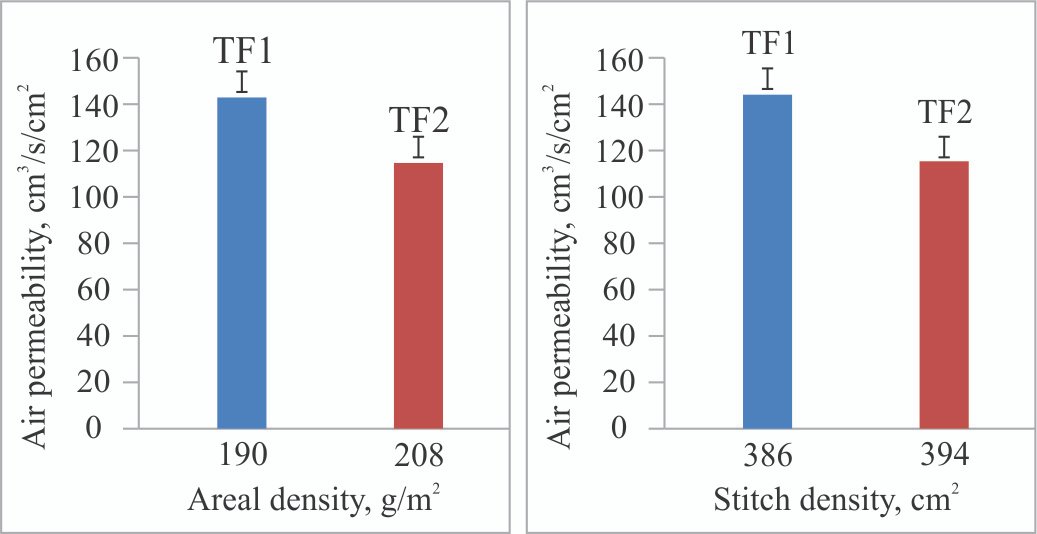

Air permeability

Air permeability is the most important property of knitted fabrics for sportswear application. The evaluation of air permeability and its relationship with physical parameters of the fabric, such as areal density and stitch density are reported in Fig. 5 below. In general, the air permeability decreases with the increase of fabric weight when linear density is same. In TF2 structure, with the increase of fabric weight, the fabric becomes denser resulting in increase of more amount of gap between the loops and gap size becomes smaller. As a result, ultimately passage of air from inner to outer and outer to inner is high for TF1 structure than TF2 structure.

Thermal conductivity

The thermal conductivity mainly depends upon on the physical characteristics of fabrics such as thickness, areal density and air permeability. It is observed from Fig. 6, as the thermal conductivity of TF2 structure was influenced by areal density. As the fabric weight increases, the thermal conductivity also increased. The amount of fibre per unit area increases and the amount of air layer decreases, as the weight increases. It is known that thermal conductivity values of fibres are higher than the thermal conductivity of entrapped air.

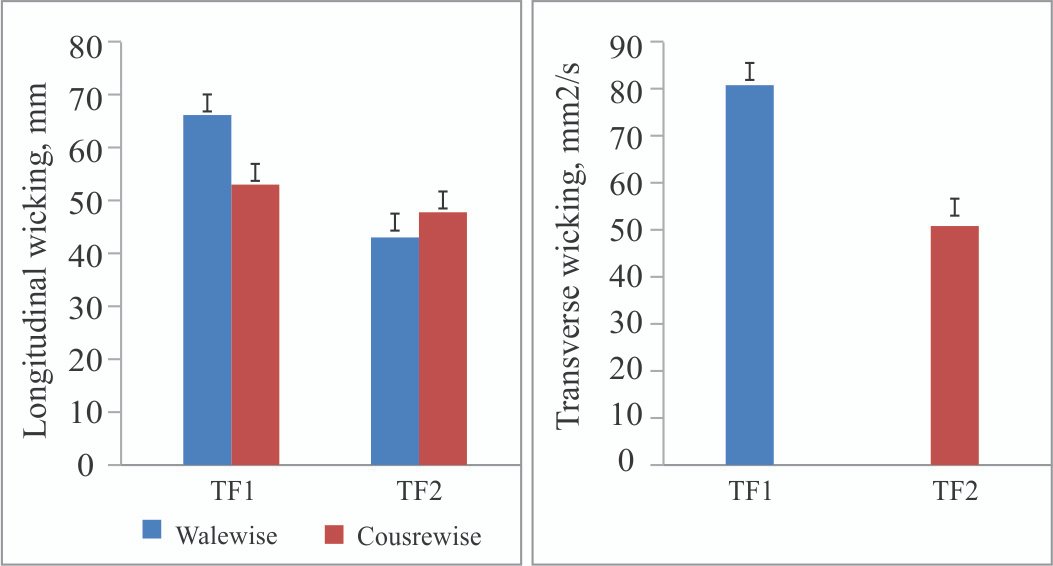

Wicking

Wickability of the fabric mainly depends upon the fabric construction, yarn regularity and type of fibre and its characteristics. It can be observed from the Fig. 7, that the wickability of modal layer structure (TF1) is higher than the bamboo layer structure (TF2). The wickability of modal is found to be higher than bamboo, the reason behind is that modal fibre has smoother yarn surface which leads to good capillary action. Even though polyester which has same characteristics and plays as inner layer for both structures TF1 and TF2; the wickability values differs for both the structures due to composite fabric wicking effect. Faster the rate of wicking better will be the sweat transporting ability and the wearer feels more comfortable. Analysis of transverse wicking characteristics of fabric is more important than longitudinal wicking because perspiration transfers from the skin involves its movement through the lateral direction of fabric. It is also absorbed form the Fig. 3 (a) and (b), the wickability is more in wale-wise direction as compared to course-wise direction. This is due to the fact that the transfer of water is easier in wale-wise direction due to the better capillary action in wale-wise manner.

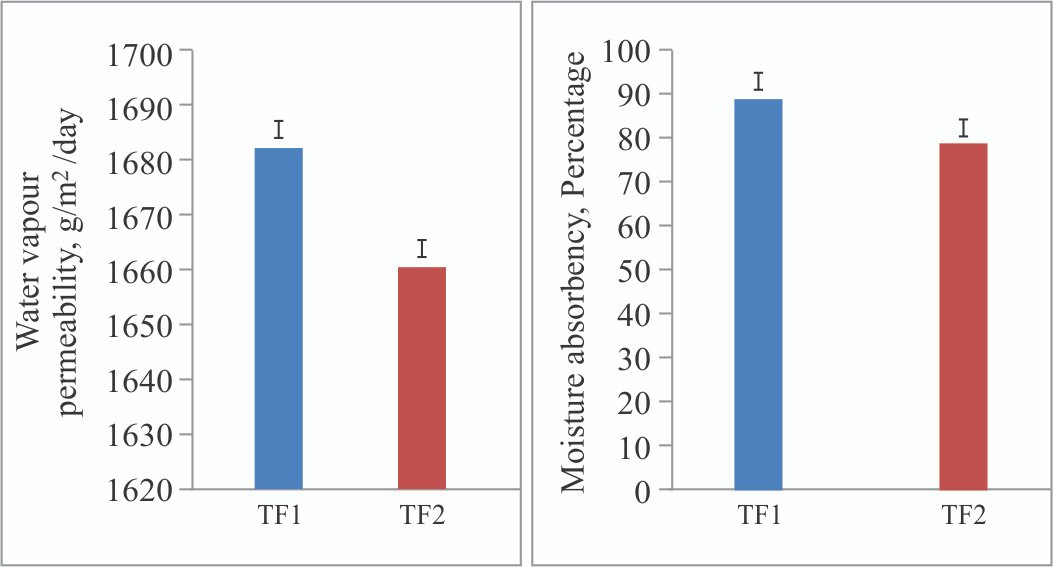

Water vapour permeability

From the Fig. 8, it is apparent that TF1structure with modal as outer layer has a higher water vapour permeability, while bamboo as outer layer TF2 structure exhibits lower value. Normally, micro denier polyester as a middle layer provides better water vapour permeability because of larger surface area and channelled fibre structure. This channelled structures form a transport system that pulls moisture away from the skin to the outer layer of fabric. Here, the nature of material affects the water vapour permeability significantly with regards to tri-layer knitted fabrics, modal shows higher value than bamboo yarn.

Moisture absorbency

When fabric is subjected to heavy sweating conditions, not all the absorbed sweat by the fabrics absorbs can be given off to the atmosphere instantaneously. So to prevent the wearer from feeling wet and clammy, the moisture should be stored in the fabric. Maximum absorbency was found in TF1 followed by TF2 (Fig.9), because modal is a regenerated cellulosic fibre, it is having uniform structure and porosity than bamboo. The modal layer structure has quicker absorbency than bamboo layer structure even though the inner layer is same for both the structures. Moreover, the surface energy of modal is high and picks-up moisture more readily.

Drying behaviour

Moisture transfer is a critical factor for thermoregulation of the body heat. Moisture on skin or clothing increases the heat loss of the body and also affects the overall performance and endurance of the body. In this regard, stitch density and areal density seems to have affected the drying ability of fabrics. Fig. 10 states clearly, the higher drying ability corresponds to structure (TF1) with the lowest mass per unit area and lower drying ability to structure (TF2) with highest mass per unit area. In TF1 and TF2 structures, thickness is same whereas areal density differs between the structures.

Effect of fibre type on air permeability, thermal conductivity, wicking, water vapour permeability, moisture absorbency and drying behaviour

Table 4 shows the ANOVA statistical analysis results at 5 per cent significance level. The air permeability values of the trilayer knitted fabrics shows significant difference within the fibre variation (F=7.745 in comparison with Fcrit =5.318) at degree of freedom (df) of 9. Thermal conductivity values of tri-layer knitted fabrics show significant difference within fibre types at 5 per cent significance level (F=357.14 & Fcrit = 5.318). The fibre type also influence the wicking characteristics of fabrics, shows significant difference (F=199.35 & Fcrit = 5.318) at degree of freedom (df) of 9. Similarly for horizontal wicking, shows significant difference (F=11.65 Fcrit = 5.318) at 5 per cent significance level. Water vapour permeability is greatly influenced by fibre type show significant difference (F=3554.93 & Fcrit = 5.318) at 5 per cent significance level. The moisture absorbency of two structures shows significant difference (F=18.03 & Fcrit = 5.318) within fibre types at degree of freedom (df) of 9. The drying behaviour of tri-layer knitted fabric shows significant difference (F=12.00 & Fcrit = 5.318) at degree of freedom (df) 9.

Wear trial assessment

The purpose of wear trial assessment is to know the suitability of sports activity with respect to the product design and climatic condition. The developed sportswear was given to basket ball and badminton players. The properties such as air permeability, thermal conductivity, wicking, water vapour permeability, moisture absorbency and drying behaviour have been chosen to study the wear trail assessment of different sport activities. The wear trail assessment is fully based on the psychological perception of the sports person which is rated within five scale rating. The Spearman’s Rank Correlation Co-efficient is used for finding out the correlation between the tri-layer structures TF1 and TF2. In Spearman’s formula, repeated ranks is added to find out the co-efficient of rank correlation. The value of rank correlation co-efficient, r = -0.225; Since the rank correlation co-efficient between TF1 and TF2 is negative, it can be concluded that the two structures TF1 and TF2 are not having nearest approach with respect to above said properties.

Conclusions

- Air permeability of modal layer structure is higher than bamboo layer structure due to decrease in stitch density and areal density

- It is observed that air permeability and areal density of fabric influences the thermal conductivity. It is high for bamboo layer structure

- The wickability, moisture absorbency, water vapour permeability and drying behaviour is greatly influenced by fibre type. The factors which influence the fabric properties are surface of fibre, smoothness, channelled structure and porosity of fibre

- From the experimental and wear trial assessment results, it is evident that layered structure provides comfort to basket ball and badminton players during playing. The modal layer structure (TF1) provides good thermal comfort to the wearer

By T Suganthi1, P.Senthilkumar 2, 1Department of Fashion

Technology, Angel College of Engineering and Technology,

Tirupur, India 2 Department of Textile Technology, PSG

College of Technology, Coimbatore, India 1 Corresponding

Author’s E-mail: suganthi.ft@gmail.com